Coil winding machine manufacturers: What are the common problems of coil winding machine?

Coil winding machines are capable of winding various sizes of coils, commonly square and round coils and directional coils. When setting up, there will be some differences when winding different coils. It is necessary to set the parameters correctly, adjust the winding tension and threading form, and then only surround better crafts and more beautiful coil products. At the same time, the coil winding machine may encounter various problems during the operation, Z common phenomena are mainly the following conditions.

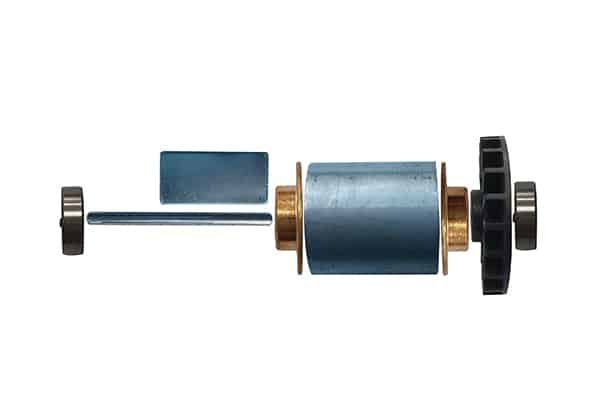

Coil winding machine manufacturer

1. The coil wire is not neatly wrapped around. When this situation arises, it is necessary to analyze whether the problem is generated during normal processing or after the replacement and commissioning of the product. If it is the former condition, most of the conditions are caused by hardware problems, if the latter condition, it is usually a setup problem. Hardware problems may be due to the loosening of the tooling fixture, the loosening of the fastening screws of the wiring mechanism, the lack of lubrication environment of the wiring mechanism and lead to the stepper motor running under load and lead to wiring failure .

2. The orientation of the spindle block is not precise enough, which is also a frequent condition of the active winding machine. This condition is mainly caused by braking problems. Like a loose brake pad, or a worn out black brake pad. In addition, it is strongly related to the setting of the braking time. If the setting time is lacking, it will cause the spindle to be positioned incorrectly. To solve this problem, you need to replace the brake pads or adjust the braking time from scratch.

3. Inaccurate winding of coils, or errors in the number of winders, mainly due to sensor or controller problems, resulting in the winder not working properly, it is necessary to make the winder manufacturer to repair it .

4. Coil winding machine operation during the abnormal sound. The difference in sound is used to determine whether the winding machine has abnormal problems. Of course, this requires professional judgment.

During the operation of the coil winding machine, the limbs cannot be close to the rotating parts after the winding machine is started. If adjustments are required, it is necessary to suspend the operation of the equipment first. Once adjustments are made, make sure you are safe and start from the beginning. In addition, the operator should not wear gloves, should not use sleeves, and should tie long hair. If the winder makes unusual noises, it is necessary to stop operation immediately and have it repaired by a professional.

WhatsApp/Wechat:+86 13075286997

電子郵件: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]