In the convenience of bringing at the same time, the automatic winding machine settings debugging difficulty has increased a lot. In the use of the winding machine, many customers will be unable to start its settings, I am here today to “save” everyone.

Winding machine features and common debugging methods for everyone to explain the following points Oh!

Familiar with the function of the equipment is the premise. Then according to their own products winding process to find out the corresponding equipment features, combined with the process to see whether the function of the equipment with the winding requirements, equipment features required in the purchase of detailed communication with equipment suppliers to avoid the purchase of equipment and winding requirements do not match, which is to pay attention to the allowable wire diameter of the equipment, weight range, line width and its accuracy, these parameters are to determine the equipment and winding These parameters are the basic data to determine whether the equipment and winding requirements.

Then you need to pay attention to the settings and data of the equipment accessories, different manufacturers of transformer winding machine equipment tension adjustment range are different, the use of aluminum and copper wire required tension is also different, the same wire diameter of aluminum wire required tension than copper wire to be small, tension adjustment will lead to the actual winding in the mold of the wire diameter becomes smaller, if it is a fine line, it will be pulled off, knotting and other phenomena, tension is too small will Tension adjustment is very critical setting, different wire diameter have a safe tension range, debugging personnel should be carefully compared, need to pay attention to the width and height of the mold, and the winding bar is matched, too tight will affect the mold loading and unloading, too loose will lead to mold shaking affect the effect of the line. Automatic winding machine generally common features are lap preset, automatic parking, forward and reverse winding, automatic cross-slot, etc..

Today few manufacturers have professional training on the operation of winding machines, stranding machines, large-torque winding machines, and no counseling on their taboos, Vacuz Machine Factory has been engaged in the development of winding machines, stranding machines, large-torque winding machines for more than a decade

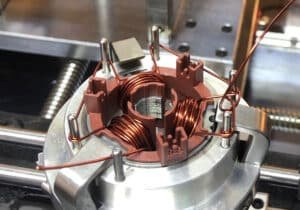

The winding machine is a special winding coil with the equipment. When operating, the handle is swung by hand, the large gear rolls and then the pinion rolls (the speed ratio is l:4 or 1:8), and the pinion rolls the main shaft. The winding die is fixed with two fastening nuts. In addition, there is a vertical screw to move the gear of the winder, so that the indication of the winder corresponds to the speed of the gear, and then the number of turns of the coil is recorded. When winding, the wire is pulled out from the wire release frame and its end is fixed to the end of the winding die, then the winding can be started.

If you purchase the winding machine is not fully automatic winding machine, then in the operation of the taboo as follows.

(1) pay attention to the wire tension to appropriate, stop too big or too small.

(2) winding energy to concentrate, the number of turns of the coil to be accurate. Stop winding the wrong number of turns.

(3) the wire turns to be placed neatly, to stop the placement of scattered.

(4) winding to stop loose and tight, the force should be uniform.

WhatsApp/Wechat:+86 13075286997

電子郵件: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]