The automated winding and arranging process of the brushless stator winding machine is the crystallization of precision machinery, automated programming and multi-parameter collaborative control. Its core rules and requirements focus on five key areas: path planning, tension control, arranging accuracy, equipment configuration and parameter fine-tuning. Let Vacuz introduce them to you below!

1. Core technical process of automated winding and arranging

1. Intelligent programming and path blueprint drawing

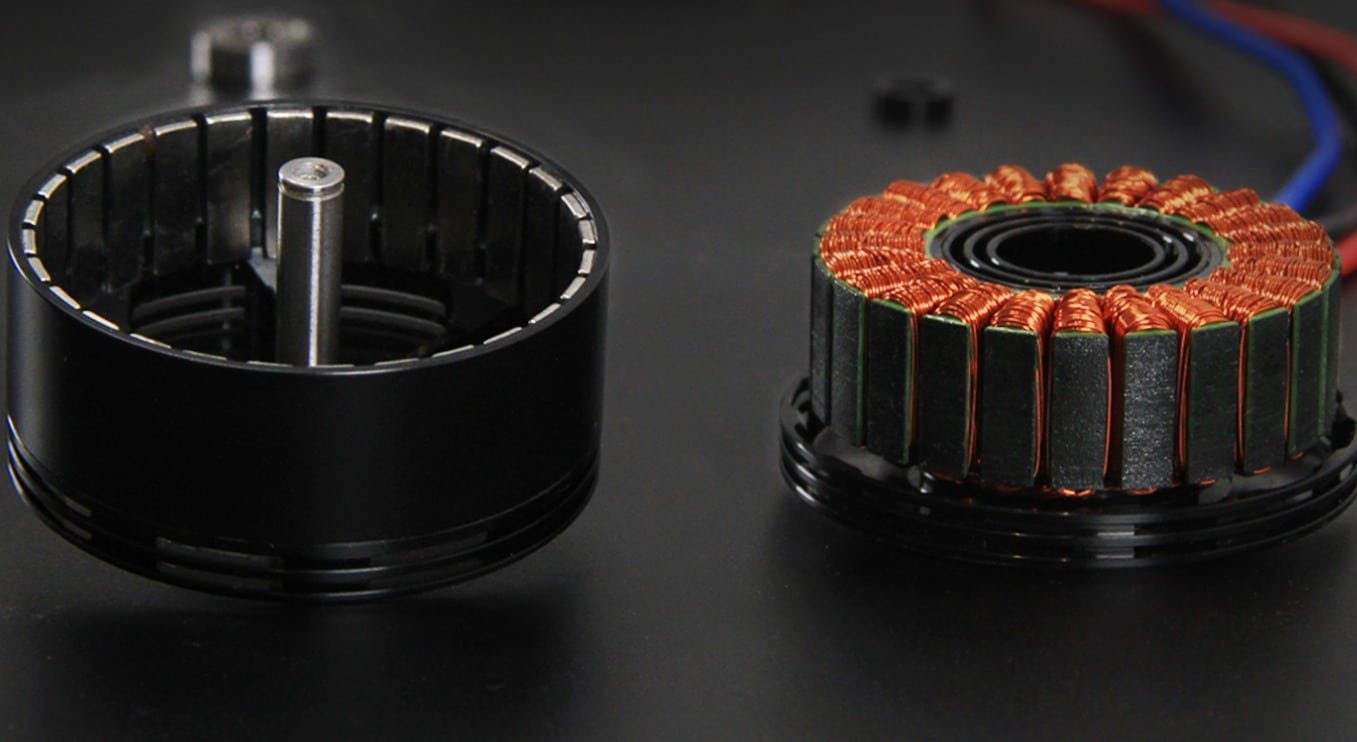

Parameter input: With the help of advanced CAD software or special programming tools, the key parameters of the stator structure, such as the number of slots, slot design and number of winding layers, are accurately entered to generate an accurate three-dimensional winding path model.

Winding sequence optimization: Optimize the winding path, effectively avoid crossing, overlapping, and sudden changes in tension, and ensure that the copper wire can fill the slot evenly and tightly.

2. Closed-loop tension control and arranging mechanism

Accurate tension control: Real-time monitoring and dynamic adjustment of the copper wire tension, keeping it within a small fluctuation range of ±0.5N to adapt to the tension requirements under different winding speeds.

Precision transmission and positioning: High-precision ball screws and linear guides are used to ensure that the repeat positioning accuracy is within ±0.05mm, providing a solid foundation for the layered arrangement of copper wires.

Wire cutting and steering mechanism: High-precision servo motors drive wire cutting knives and steering mechanisms to achieve wire cutting error and steering angle error control within a small range.

3. Real-time monitoring and intelligent correction

Laser displacement monitoring: Using laser displacement sensors, the position of copper wires is monitored in real time to ensure that the deviation does not exceed ±0.05mm.

Visual inspection system: Through advanced visual inspection systems, the winding surface is fully scanned to accurately identify and automatically correct defects such as missing wires and overlaps.

2. Core rules and technical requirements

1. Winding position accuracy

The copper wires must be arranged strictly according to the notch contour, and the error is controlled within ±0.02mm to maintain the symmetry of the magnetic circuit and ensure that the motor performance is not affected.

2. Tension consistency

The tension fluctuation throughout the process must be kept within ±3% to prevent wire breakage or coil loosening caused by sudden tension changes, thereby ensuring the efficiency and service life of the motor.

3. Interlayer insulation and filling rate

The positioning error of the interlayer insulation paper must be controlled within ±0.1mm to ensure insulation performance; at the same time, the copper wire filling rate must meet the design requirements to avoid heat dissipation problems caused by over-density or performance degradation caused by over-sparseness.

4. Repeat positioning accuracy

During the multi-slot winding process, the winding starting point error of adjacent slots must be controlled within ±0.05mm to ensure the consistency of the electromagnetic performance of the motor.

5. High-speed winding stability

During high-speed winding, the copper wire is prone to jitter, affecting the quality of the wiring. By adopting high-rigidity guide rails, closed-loop servo systems and active vibration suppression algorithms, the jitter amplitude is controlled within ±0.01mm.

6. Anti-interference of multi-wire winding

When winding multiple wires in parallel, interference between wires may cause short circuit risk. Through electromagnetic field simulation to optimize the wire diameter and spacing design, combined with real-time tension compensation technology, the short circuit risk is reduced to a low level.

III. Equipment configuration and parameter adjustment strategy

1. Hardware configuration

Wire arrangement device and mold: It is necessary to achieve high-precision coordination, and gradually adjust the position through full winding debugging until the appropriate winding effect is achieved.

Controller: Select high-quality controllers and calibrate them regularly to ensure data accuracy and control stability.

Tensioner and wire clamp: Select a suitable tensioner according to the characteristics of the wire, and adjust the wire clamp tension value to provide stable support for the wire.

2. Parameter setting

Wire harness length and spacing: Set reasonably according to product requirements and wire characteristics to avoid winding problems caused by too long or too short to affect production efficiency.

Motor speed: Control the winding speed by adjusting the motor speed, and appropriately increase the wire clamp tension to maintain stability during high-speed winding.

Wire type and specification: Select the appropriate wire type (such as copper wire, aluminum wire, etc.) according to product requirements, and confirm that the wire specifications (such as wire diameter, notch distance) match the equipment requirements.

IV. Operation and maintenance specifications

1. Commissioning stage

Step by step in manual mode to debug and observe whether the mold positioning is accurate to avoid the problem of the striker or stator slot not aligning with the die head during automatic operation.

The winding should be run at a slow speed at the beginning, and gradually accelerate to the specified range after confirming that there is no problem.

2. Production stage

Regularly check the winding status and wiring circuit, and maintain key components (such as tensioner, wire mouth, wool felt) in time to ensure the normal operation of the equipment.

Operators must wear necessary protective gear, and it is strictly forbidden to reach into the working area when the machine is running to ensure personal safety.

3. Quality inspection

After the winding is completed, salt water test is carried out to check the leakage situation. After ensuring that the leakage value meets the standard, mass production is carried out to ensure product quality.

How does the brushless stator winding machine automatically wind and arrange the wires? What are the rules and requirements? Vacuz has briefly explained them above, and I hope this knowledge can help you!

電子郵件: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]