The price of a brushless DC stator winding machine is influenced by many factors, including model, features, brand, and configuration. So, how much does a brushless DC stator winding machine cost? How do you choose a winding machine based on your needs? Below, Vacuz provides a brief introduction!

1. Economy Machines: Prices range from $5,000 to $8,000. These machines are suitable for small-scale production or simple winding needs, such as single-axis winding machines or semi-automatic machines.

2. Mid-range Machines: Prices range from approximately $9,000 to $20,000. These machines typically feature multiple stations, automatic wire routing, and high-precision control, making them suitable for small to medium-volume production.

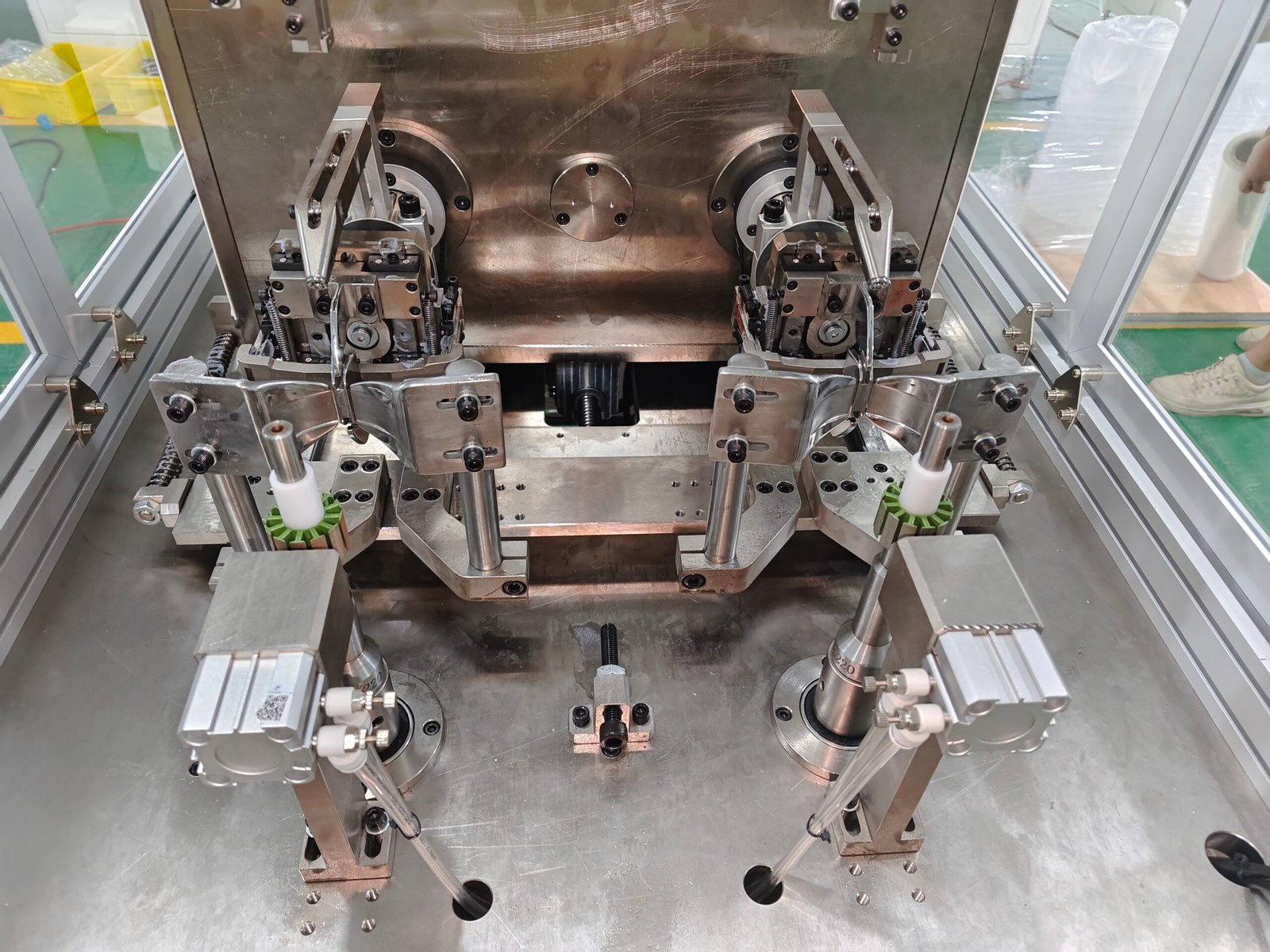

3. High-end Machines: Prices exceed $22,000. These machines are suitable for large-scale production or high-precision requirements, such as six-station high-speed internal winding machines or fully automated production lines.

Factors influencing price include the number of workstations (the more workstations, the higher the production efficiency, but the higher the price), the degree of automation (fully automatic equipment is significantly more expensive than semi-automatic equipment), precision and stability (high-precision equipment is more expensive but reduces scrap), and brand and after-sales service (equipment from well-known brands may be more expensive but offer better after-sales service).

Selection Guide:

1. Stator Slot Orientation:

Inward-facing slots: Suitable for internal winding machines (such as needle winding machines), suitable for precision winding requirements, such as model aircraft motors and small water pumps.

Outward-facing slots: Suitable for external winding machines (such as flying fork winding machines), which offer faster winding speeds and are suitable for stators or rotors with outward-facing slots.

2. Stator Size:

Outer Diameter: Stators with larger outer diameters require equipment with fewer workstations (such as two), while stators with smaller outer diameters can use multi-workstation equipment (such as four or six) to improve efficiency.

Height: For taller stators, consider the oscillating needle and wire feeding methods to prevent wire breakage and disorganized winding during winding.

3. Wire Diameter and Winding Method:

Wire Diameter: For finer wire diameters, a precision winding machine should be selected to control the tension and prevent wire breakage. For thicker wire diameters, the winding speed should be reduced and the tension increased to ensure coil tightness.

Winding Method: For single-wire winding, basic equipment can be used, while multi-wire winding requires tension control and synchronized winding functions, which are suitable for high-power density motors.

4. Wire Outlet and Wire Feeding Method:

Wire Outlet Method: Depending on the stator structure, choose top, bottom, or side wire outlet to ensure neat wire arrangement.

Wire Feeding Method: Direct wire feeding is suitable for simple applications but may damage the wire. Guide wheel wire feeding or tension wire feeding can reduce wire damage, improve winding quality, and are suitable for high-precision requirements.

5. Production Scale and Budget:

For small-scale production, choose economical equipment to balance cost and efficiency.

For large-scale production: Invest in high-end equipment and reduce long-term costs through automation.

We hope this guide helps you better select the right brushless DC stator winding machine. If you have any other needs or questions, please feel free to let Vacuz know!

電子郵件: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]