Automated production lines are more suitable for mass assembly of brushless motor rotors. However, automated production line design also demands high standards, such as line coordination and flexibility. So, how can coordination and flexibility be achieved in a brushless rotor production line? How can assembly accuracy be optimized? Vacuz will explain!

Two Sets Double Stations Drone Motor Automatic FPV Stator Core Winding Machines + Two Sets BLDC Drone FPV Rotor Core 2 Sides Dynamic Balancing Machines Shipment

I. Improving Collaboration: Building a Closed-Loop Control System with Equipment Interoperability and Data-Driven Control

1. Hardware Collaboration

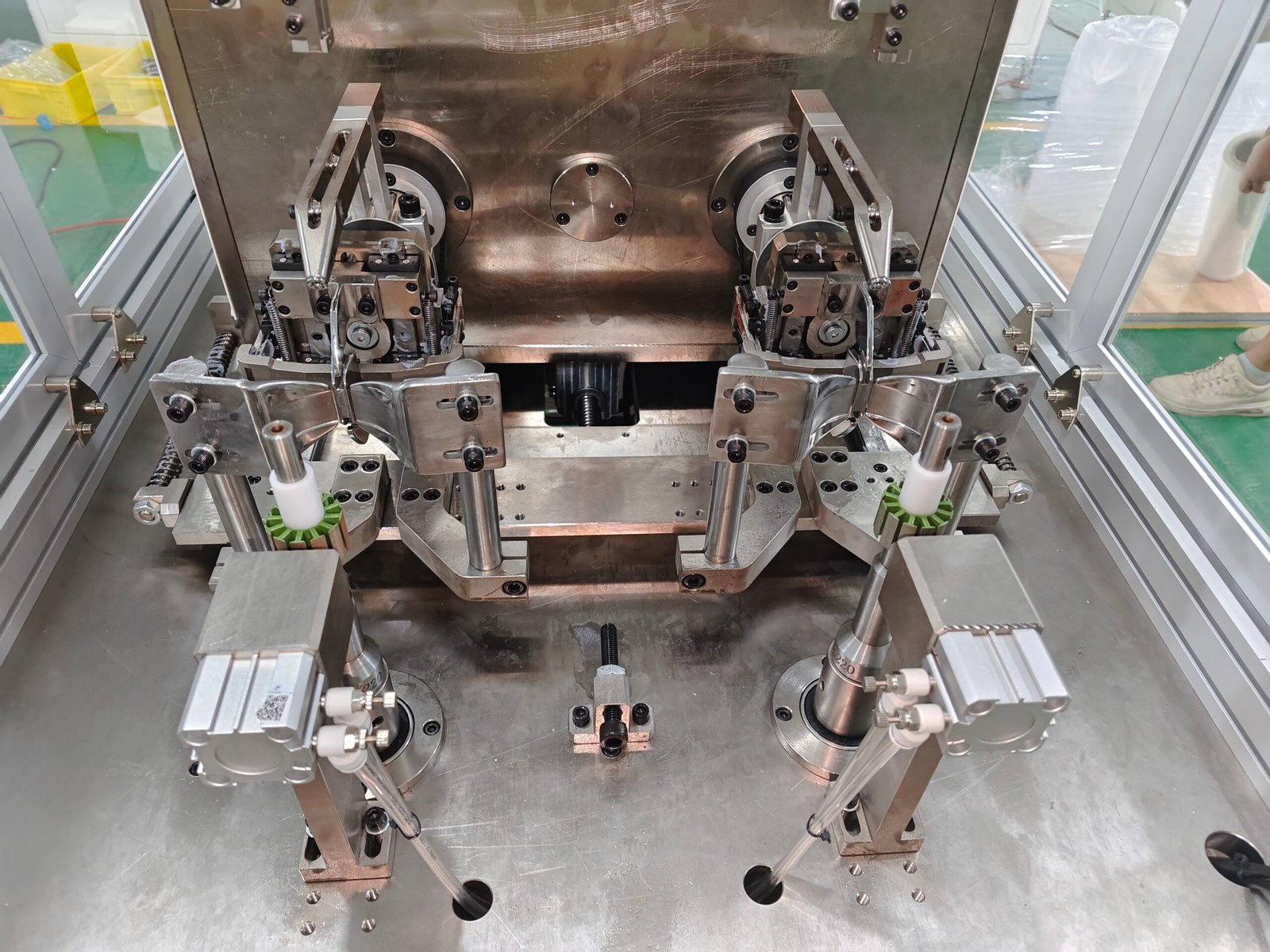

Modular Design: Utilizes standardized functional modules, such as shaft loading, magnetic press-fitting, and dynamic balancing testing. Quick-change tooling enables efficient switching of equipment functions, improving production line compatibility.

High-Precision Drive: Utilizes precision ball screws and linear guides, combined with high-speed servo motors, to ensure accurate multi-axis tracking, enhancing production efficiency and product quality.

2. Software Collaboration

Full-Process Data Collection: RFID technology enables material batch traceability, and PLC-based real-time data collection of key parameters provides data support for production decision-making.

Intelligent Scheduling Algorithm: Dynamically adjusts equipment cycle times based on production plans, balances loads across processes, and improves overall production line efficiency.

3. Human-Machine Collaboration

Error-Proofing Design: Installs error-proofing devices, such as photoelectric sensors, in key processes to reduce error rates.

Visual Monitoring: Builds a digital twin production line, mapping physical equipment status in real time to proactively identify and resolve problems.

II. Flexibility Optimization: Achieving Flexible Manufacturing and Adaptive Production

1. Equipment Flexibility

Multi-Station Parallel Operation: Designs multi-station parallel modules to improve production efficiency.

Rapid Mold Change Technology: Utilizes a pneumatic rapid clamping mechanism to shorten production line changeover time and enhance production flexibility.

2. Process Flexibility

Intelligent Adaptive Assembly System: Incorporates machine learning algorithms to automatically adjust assembly parameters, improving assembly accuracy and efficiency.

Vision-Guided Assembly: Incorporates high-resolution cameras and deep learning algorithms to accurately position parts.

3. Management Flexibility

Lean Layout Optimization: Adopting U-shaped or Cell-shaped production line designs shortens material handling distances and improves production efficiency.

Predictive Maintenance System: Using sensors and big data analytics to predict equipment failures, reducing failure rates and maintenance costs.

3. Assembly Precision Optimization: From Source Control to Full-Process Traceability

1. High-Precision Equipment and Process Control

Nano-Scale Machining Center: Using precision machine tools to machine key dimensions and ensure rotor dynamic balance.

Closed-Loop Tension Control: Real-time adjustment of wire tension during the winding process improves coil fill rate consistency.

2. Online Inspection and Feedback Correction

Multi-Parameter Testing Station: Integrates multiple sensors to monitor key parameters in real time to ensure assembly quality.

SPC Process Control: Implements statistical process control for key processes, analyzes process capability, and ensures product consistency.

3. Full-Process Traceability and Quality Control

MES Traceability System: Records production data for each rotor, supports batch or unit traceability, and improves the efficiency of locating quality issues.

Zero-Defect Management: Implements the PDCA cycle, combining error-proofing devices and online inspections to achieve zero-defect production.

Motor Production Line

How do you achieve coordination and flexibility in brushless rotor production lines? How can assembly accuracy be optimized? Vacuz has provided a brief explanation above. We hope this information is helpful!

電子郵件: sales@vacuz.com