The core and detailed requirements for fully automatic stator winding machine mold design encompass high-precision machining, structural adaptability, material wear resistance, user-friendly operation, and environmental adaptability. What are the specific requirements? Vacuz will provide a brief introduction.

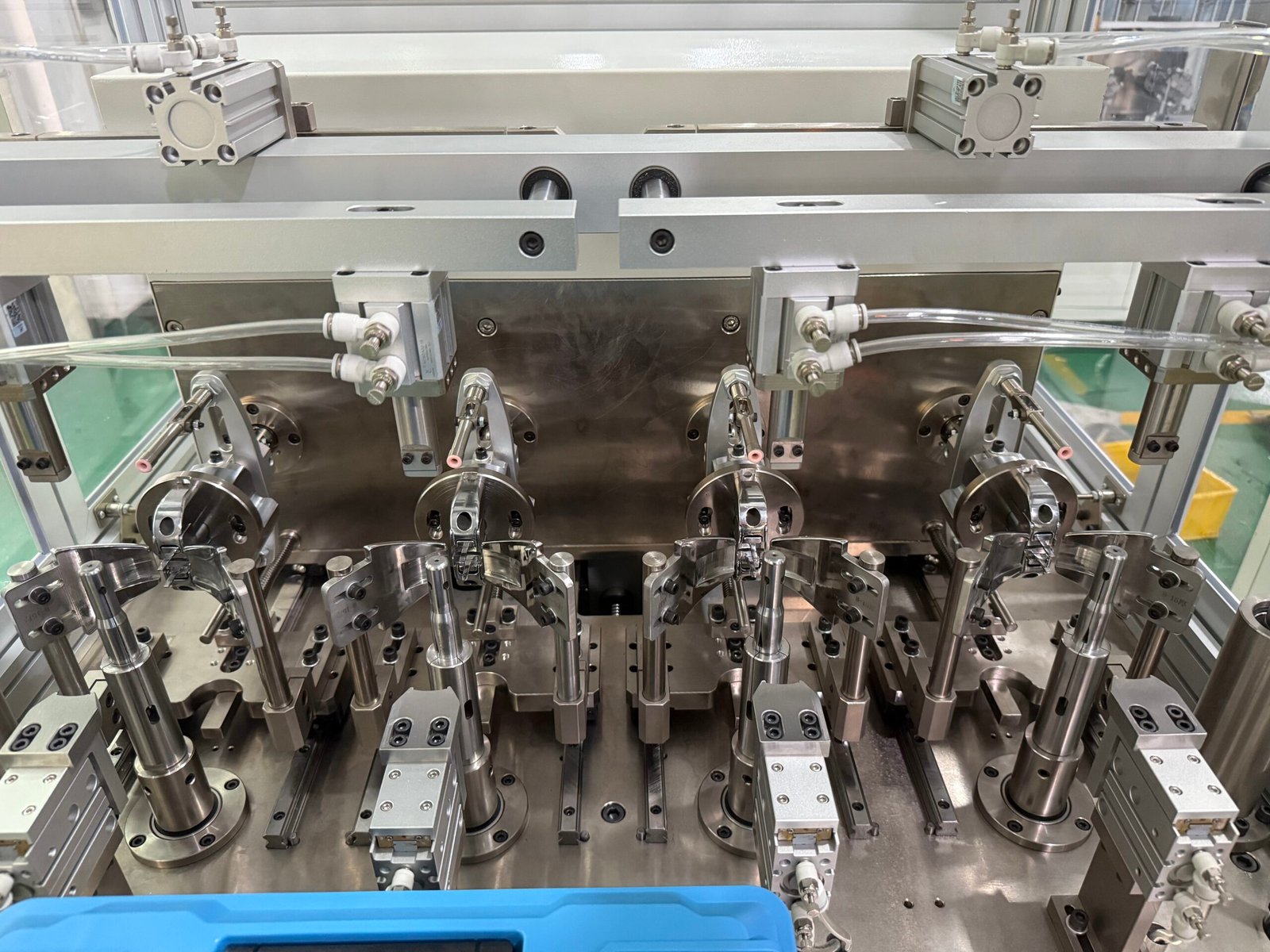

Vacuz 4 Stations DC Ceiling Fan Motor Automatic Outer Stator Coil Winding Machine Equipment

I. Core Design Requirements

1. High-Precision Machining: The tolerances of all mold components must be strictly controlled. For example, the notch dimension deviation must be ≤ ±0.02mm, and the surface must be polished to a smooth, burr-free finish to reduce wire friction.

2. Structural Adaptability: The mold must be customized according to the stator size and winding method to ensure interference-free assembly and disassembly.

3. Material Selection: The main body is constructed of high-strength alloy steel, achieving a hardness of HRC58-62 after heat treatment. The surface can be hard chrome plated or ceramic sprayed to enhance wear and corrosion resistance.

II. Key Design Details

1. Optimized Wire Passing and Stopping Areas: Designed arc guides prevent wire breakage, and positioning grooves ensure accurate wire end fixation.

2. Fastening and Anti-Loosening Design: A quick-clamping mechanism and anti-loosening screws ensure the mold remains stable and prevents loosening during the winding process.

III. User-Friendly Operation Design

1. Lightweight Structure: The mold weight is kept within a reasonable range, making it easy to carry manually.

2. Identification System: Information such as the stator model and winding parameters are engraved for quick identification and debugging.

IV. Environmental Adaptability Design

1. Temperature Control Design: An embedded temperature sensor monitors and controls the mold temperature in real time to prevent thermal deformation.

2. Dust-Proof Design: The design is enclosed, with dust covers installed at key locations and regular cleaning to maintain accuracy.

V. Verification and Optimization

1. Simulation Testing: Use CAD software to simulate mold motion and optimize mold design.

2. Actual Winding Test: Check indicators such as winding accuracy, wire arrangement quality, and wire damage rate, and adjust the mold design based on the test results.

Vacuz 4 Stations DC Ceiling Fan Motor Automatic Outer Stator Coil Winding Machine Equipment

How should the mold for a fully automatic stator winding machine be designed? What are the detailed requirements? Vacuz has provided a brief explanation, and we hope that it provides you with a clear understanding of mold design. If you have any other needs or feedback, please feel free to let Vacuz know.

電子郵件: sales@vacuz.com