Generally speaking, winding machine manufacturers in the factory before the winding equipment is commissioned, but as a motor manufacturer, the inspection process is indispensable, the main purpose is to ensure that the stator winding stable and safe, although there is no clear test items, but the approximate inspection procedures or to know the machine.

Many friends may not know how to check the stator winding machine, the following Vacuz teach you some common methods and notes it!

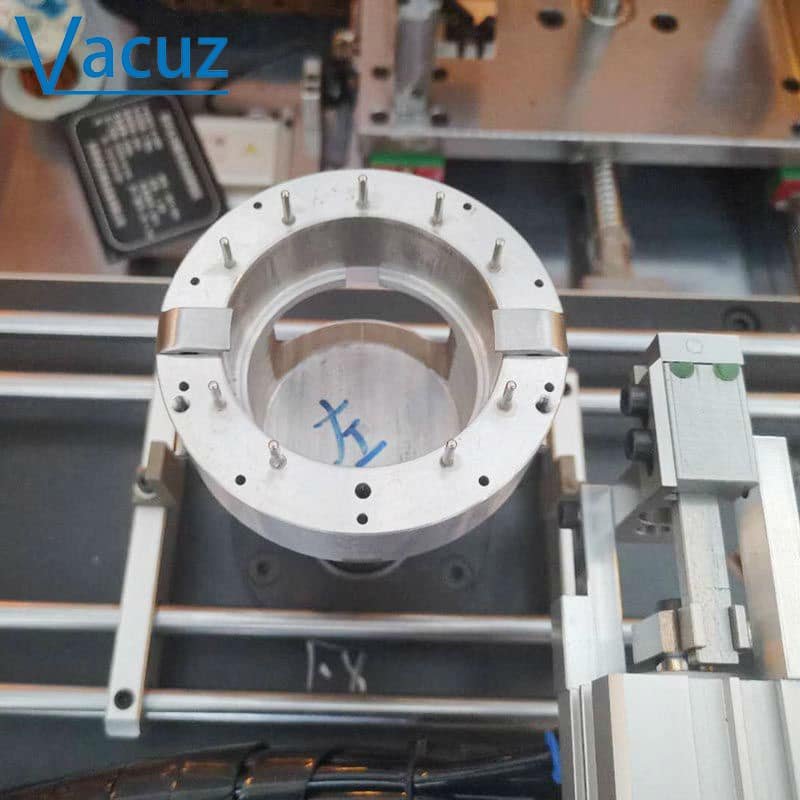

1. Appearance and parts inspection

After disassembling the wooden box, pay attention to check whether there is no bump, the machine as a whole is complete, check whether the parts are complete, you can check against the table one by one, if there is a lack of, direct photo contact winding machine after-sales personnel.

2. Stator winding machine installation

Legitimate winding machine manufacturers, are door-to-door installers, generally and the machine almost together to the installation can be installed according to their needs, choose a flat, wide site, require the installer to install the machine to ensure that the lubrication of the sliding parts, as well as the

shaft and the coaxiality between the sleeve hole.

3. Idle test run testing

After the installation of the winding machine, connected to the power supply, air supply, the technician turned on the machine, start idling operation, as long as possible, about half an hour, observe the bearing components and sliding parts, idle each action is normal, try the emergency stop effect is good.

3. Hanging line running test

After determining that there is no problem in idling, start to hang wire operation, pay attention to observe the winding lineup, whether the line is correct, whether the count is accurate, whether the winding process is smooth, after winding the stator for salt water test, to see whether the coil quality meets the requirements, if there is a wound line, need to adjust in time.

4. Operation training

As a professional winding machine manufacturers, after-sales training is an important link, try to find a few more staff corresponding to the post, look carefully, learn carefully, with a pen or shoot video, record the correct operating steps, especially the touch controller stator parameters, program calls, and mold replacement, etc., operate a few times to ensure that they remember, try a few times on their own to ensure that the machine is stable, no operation Only after a few attempts to ensure the stability of the machine and no problems with the operation, let the technician leave.

How to check the brushless motor stator winding machine? What are the test items? The above is a small summary of the winding machine manufacturers Vacuz and experience, motor manufacturers must ensure familiar with the entire process, so that the winding machine can be stable and normal operation, to achieve twice the result with half the effort!

WhatsApp/Wechat:+86 13075286997

電子郵件: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]