For brushless motor stator, there are two common, one is the slot inward stator, one is the slot outward stator, two stator winding way is largely different, today we talk about the inner stator winding way and features it!

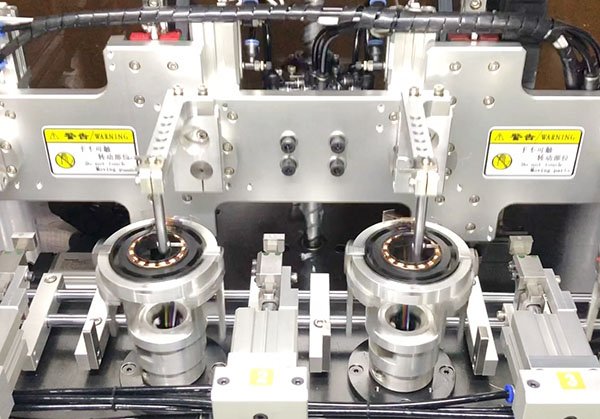

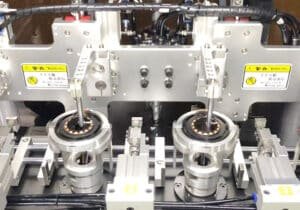

Motor inner winding machine series can be used for high precision winding of inner stator of brushless motor. Equipped with unique ultra-high speed control system and simple and exquisite structure, the specifications can be flexibly changed by moving the nozzle up and down and rotating the core, and the wire can be wound on any track.

1. By changing the computer winding program, it corresponds to different core thickness and different number of winding stator poles.

2. Under the operation of man-machine control panel, any abnormal operation and fault status will prompt operation and maintenance, the number of turns can be set arbitrarily, and it can stop at any position within the specified 360 degree range, winding is simple and fast, shortening the winding time and improving the overall production efficiency.

3. The number of turns per winding layer can be flexibly changed to achieve simple and convenient programming for different product types.

4. With unique special software, unlimited upload, download and storage.

5. Easy to master by simple training due to high performance control system and servo motor, it ensures stable enameled wire position and shortens time, manual or automatic robot loading and unloading method can be selected according to customer requirements, each unit has been standardized and easy to replace and disassemble.

The above is the brushless motor winding machine winding mode and common features, to understand these basic knowledge, in order to better use the winding machine, to bring more help to our production!

WhatsApp/Wechat:+86 13075286997

電子郵件: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]