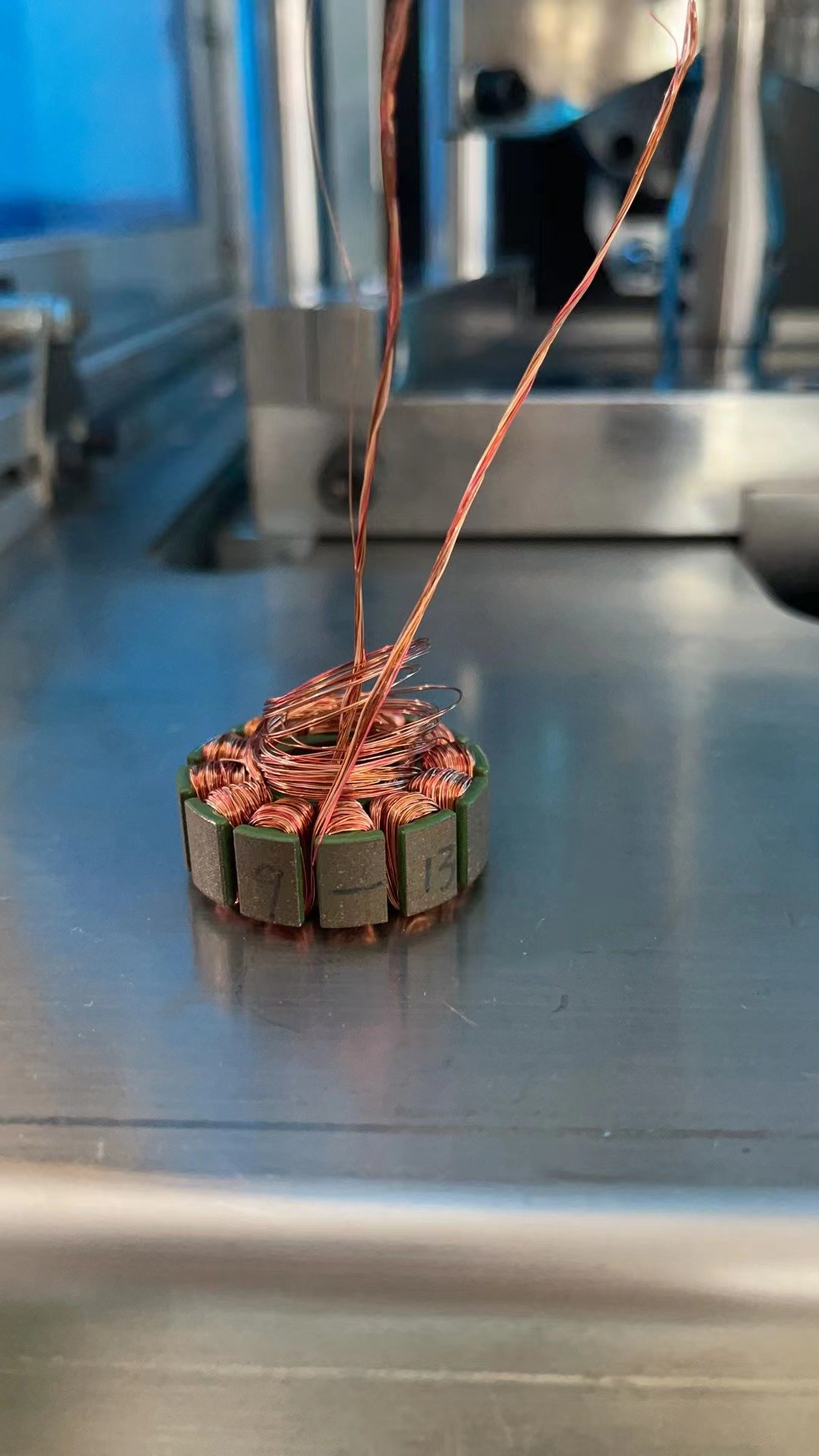

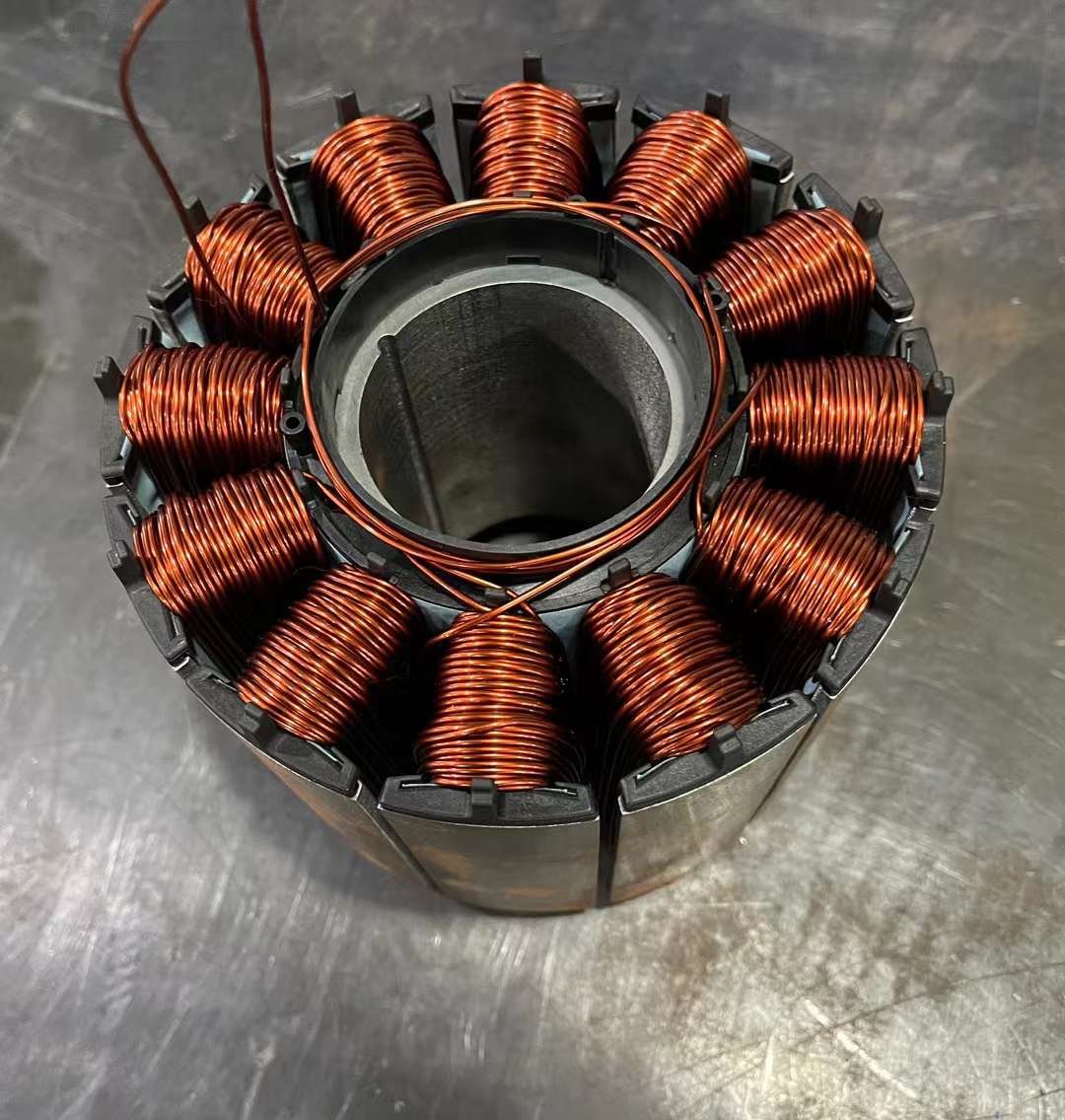

Flying Fork Winding Machine, as the core equipment for robotic brushless motor stator winding, plays an indispensable role in the field of motor manufacturing by virtue of its unique design and technical advantages. It skillfully utilizes the high-speed rotation of the flying fork to work in concert with the die head, die tongue, stator bar, guard plate and other precision parts to achieve accurate winding of enameled wires. This type of winding is not only fast, but also ensures that each slot is wound evenly and tightly, which meets the high requirements of stator winding for robotic brushless motors.

In order to ensure the stable quality of the flying fork winding machine, the following measures can be taken.

1. At the purchase stage, we tend to choose those well-known brands and manufacturers that enjoy a good reputation in the market and have rich production experience. These brands and manufacturers usually have a more stringent quality control system and perfect after-sales service system, which can provide us with higher quality equipment guarantee.

2. After the arrival of the equipment, we will immediately carry out on-site test acceptance. Through the actual running test, we can intuitively understand the operating status of the equipment and winding effect, to ensure that the equipment has reached our expectations before officially put into production.

3. Timely find and solve any problems in the process of equipment trial, to ensure that the equipment can be put into production smoothly.

4. We also pay great attention to the training and maintenance of operators. We will provide professional training courses for operators to help them master the operation and maintenance skills of the equipment. This can not only improve the operating efficiency of the equipment, but also extend the service life of the equipment.

5. We formulate detailed maintenance and repair plans for the equipment, and carry out regular cleaning, lubrication, inspection and other maintenance work on the equipment to ensure that the equipment always maintains a good operating condition.

6. We strictly abide by the quality control process and keep a strict check on every process. Whether it is the procurement of raw materials, the control of the production process or the inspection of the finished product, we strive to achieve excellence. This not only ensures that the quality of the products meets the requirements, but also enhances the brand image and market competitiveness of our enterprise.

In summary, the quality and performance of the flying fork winding machine, as the key equipment for robotic brushless motor stator winding, is crucial to the entire production process. By taking a series of strict measures to ensure that the quality of the equipment meets the requirements, we can provide a strong guarantee for the production of robot brushless motor stator.

電子郵件: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form]