Brushless DC motors need a driver? Many friends often ask this question, the answer is definitely need, why?

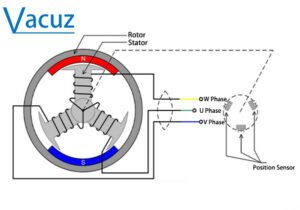

The principle of motor operation is: the stator generates a rotating electromagnetic field, which attracts the rotor to follow the rotation, thus driving the load.

Because the direction of the alternating current used in AC motors varies periodically, a rotating electromagnetic field can be generated directly in the stator, while the current in brushless DC motors is unidirectional.

In order to produce a rotating magnetic field in the stator of a brushless motor, two methods are usually used: DC brushed motors change phase by brushes, and DC brushless motors change phase electronically by a driver. Brushless motors must have a driver to achieve electronic commutation in order to rotate. However, the driver of a brushless DC brushless motor does not necessarily have a separate driver housing and can simply be a driver circuit placed in the motor.

Brushless DC motors use an electronic commutator instead of a mechanical commutator. Due to electronic commutation, the brushless DC motor requires a drive circuit. The commutation circuit of a brushless DC motor consists of two parts, drive and control, which are not easily separated, especially for low power circuits, and are often integrated into an ASIC.

A Hall sensor inside the motor senses the current position of the motor rotor, which then determines the sequence of power transistors in the inverter based on the stator winding. The current flowing through the motor coil generates a magnetic field that interacts with the rotor’s magnets to rotate the motor.

Of course, this simple drive only ensures the basic rotational function of a DC brushless motor. Brushless DC motors also have other functions such as PWM speed control, FG signal output, analog signal speed control, external potentiometer speed control, open/closed loop control, etc., which require more complex circuits to implement. We have integrated multiple functions on the PCB board to implement the control.

Brushless DC motor is a kind of permanent magnet brushless synchronous motor, whose performance parameters, model, supply voltage, output power, phase angle, presence or absence, photoelectric switch or self-identification function must be matched with the controller of brushless DC motor to work properly.

Brushless DC motor has no brushes and commutator, so if it wants to keep the direction of rotation, it needs an electronic commutator. The electronic commutator is controlled by the driver and the brushless motor controller can also control the motor start/stop, forward/reverse, speed regulation, overvoltage, overcurrent and undervoltage protection. Therefore, it is necessary to have a brushless motor controller. Even if the DC brushless motor is directly energized, it will not work.

The above is the principle and structure of brushless DC motor operation, brushless DC motor definitely needs a driver, otherwise it can’t make the motor run, master these basic tips to understand more about brushless DC motor.

WhatsApp/Wechat:+86 13075286997

电子邮件: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form].