When it comes to brushless power tools, we may not be unfamiliar at all, everywhere in life, like electric wrenches, hammers, drills and so on, whether for decoration or maintenance are useful, favored by the majority of customers, but we know the brushless power tool motor internal composition?

Brushless power tool motor internal, mainly by the stator and rotor, the rotor consists of many parts, before mainly by manual assembly, now many manufacturers have adopted the automated production line mode, then how to achieve the automated production line mode? Let’s take a look!

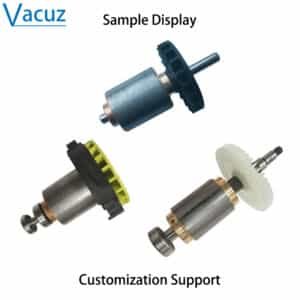

In general, mainly according to the brushless motor product parameters, to customize the rotor production line, different products, the production line process has some differences, the approximate process and design ideas are as follows.

First of all, the rotor core loading process, then the initial positioning of the core, the next magnet dispensing, can be single-headed, double-headed, multi-headed dispensing, and then through the automatic insertion of the magnet equipment, magnetic insertion work, the next will test the magnetic flux to ensure compliance with the requirements, and then is the process of press-fit core and balance block and airfoil, and then will do a dynamic balance test, installed bearings, installed gear, followed by Laser marking and robotic material collection process.

With the rotor automatic assembly equipment, the production of rotor is no longer a trouble, it can be done in one step, easy and simple, and can also save a lot of costs.

WhatsApp/Wechat:+86 13075286997

电子邮件: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form].