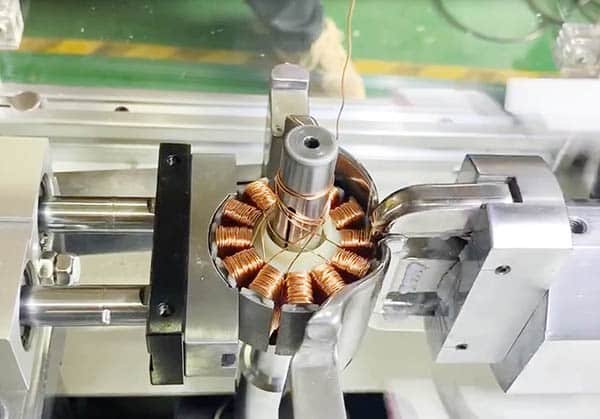

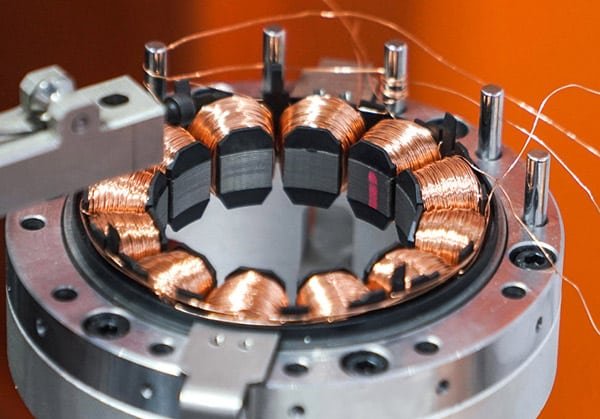

Motor stator winding is more critical, especially the winding effect, the configuration and stability of the winding machine will affect the stator winding effect, if the machine is not stable, it will not meet the requirements, so how to control the stability of automatic motor stator winding machine? How to ensure that the quality of winding effect? Vacuz give you an introduction to it!

First, cast the foundation of stability

1. Selection of excellent equipment: in the winding machine on the road to purchase, we should tend to trust the well-known brands and high-quality equipment, they are outstanding performance and stability, for the subsequent winding work to lay a solid foundation.

2. Maintenance, do not slacken: Regularly on the winding machine for meticulous inspection and maintenance, including the removal of dust, lubrication of mechanical parts, replacement of worn spare parts, etc., to ensure that the machine always maintains a good state of operation and stability.

3. Parameter optimization, accurate configuration: for the unique specifications and needs of the motor, we need to carefully configure the parameters of the winding machine, such as tension and speed fine-tuning, in order to pursue a good winding effect, to achieve the perfect fusion of accuracy and efficiency.

3. Driving advanced control system: Introducing PLC (Programmable Logic Controller) or professional controller of the winding machine and other cutting-edge technologies to realize all-round control and regulation of the winding process.

4. Real-time monitoring, instant feedback: In every subtle part of the winding operation, we utilize sensors and monitoring equipment, as if setting up a tight line of defense, real-time monitoring of the position, tension, speed and other key parameters, and through the feedback system to make rapid adjustments, to ensure that the winding process is as stable as a rock.

Second, guard the soul of winding quality

1. Carefully planning the winding program: according to the stator structure and specifications of the motor, we carefully plan the winding program, and strive to be accurate in every detail from the wire width to the stator height to ensure the tightness and stability of the winding.

2. Tension control, just right: tension, the lifeblood of the winding quality, we according to the specifications of the wire and winding requirements, accurate tension control, neither too tight nor too loose, to avoid the occurrence of broken wire or winding problems.

3. Speed control: In the pursuit of efficiency, we pay more attention to the quality of winding. Therefore, we control the winding speed within a suitable range to avoid wire loss or wire breakage caused by excessive speed.

4. Slot fullness management, keep improving: Slot fullness, as a key index to measure the degree of filling of motor stator slots, we ensure that the slot fullness reaches the standard with the help of high-accuracy automatic winding machine and accurate tension control, to avoid the increase of resistance and the increase of power loss.

5. Wire damage protection: We are well aware of the hazards of wire damage to the quality of the winding, so we optimize the process and design reasonable wiring paths to reduce the chance of contact between the wire and sharp edges. At the same time, regular maintenance of winding equipment to ensure that its components are in good condition to reduce the incidence of wire injuries.

6. Quality inspection, strict control: After the completion of the winding operation, we use an automatic inspection system to carry out a comprehensive electrical test on the windings, such as resistance test, insulation resistance test and voltage test, etc., to ensure that the electrical performance of the windings meets the stringent standard requirements.

7. Employee Training, Skill Upgrading: Employees are the guardians of winding quality. Therefore, we provide our employees with regular training and communication opportunities, aiming to improve their operating skills and safety awareness, and to minimize equipment failures and winding quality problems caused by improper operation.

In summary, through the implementation of this series of strategies and measures, we can not only ensure that the stability and reliability of the automatic motor stator winding machine has been significantly improved, but also to achieve a qualitative leap in the winding quality.

电子邮件: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form].