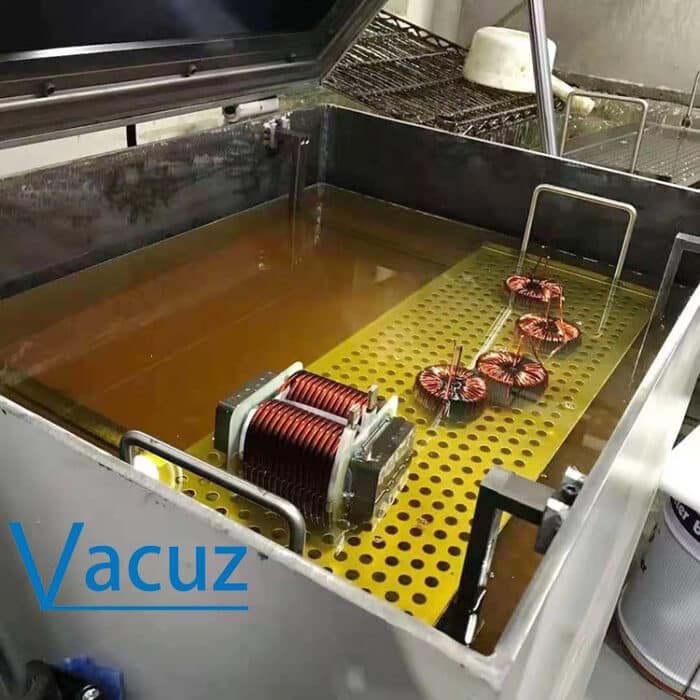

单槽/双槽 Vacuz 全自动真空浸渍变压器 环形线圈电感器浸漆机 大容量浸油机 油漆室

Description

Vacuum impregnation machine is a kind of equipment suitable for the impregnation treatment of high-frequency and low-frequency transformers, inductance coils, motors, inductors, rectifiers, metal castings, and C-shaped iron cores. It can improve the mechanical strength of the coil, insulation strength, and moisture resistance. Anti-mildew, noise reduction, and other functions; resin filling of various metal film capacitors, electrolytic capacitors, vacuum degassing process for medium/small resin crafts, and vacuum degassing process for various plastic PU raw materials. It can improve product quality, reduce production costs, save and increase efficiency, and protect the environment. The equipment generally has dozens of varieties such as assembled type, bulk type, square cylinder type, single-machine multi-cylinder type, multi-machine single-cylinder type, and multi-machine multi-cylinder type.

机器功能

1. Input: AC 380V 3-phase 4-wire 50Hz (power: 1HP)

2. Use 50KG hydraulic rod to support the top cover. The top cover is sealed with silicone rubber around it, and the cover can be snapped off quickly.

3. The stepper motor is used to drive the precision ball screw to drive the lifting impregnation of the sub-trough,

The lifting height can be preset (the maximum stroke of the sub-slot is 60mm; the displacement accuracy is ±0.05mm)

4. The screw elevator has a large bearing capacity and high control accuracy. The pins will not stick to vanillin water and do not require secondary tin plating.

5. Controlled by the PLC controller, various impregnation modes can be preset, and it has the function of eliminating air bubbles in a timely manner;

6. Automatic opening and closing of the box cover, automatic vacuuming for the second time, saving time and effort, environmental protection, energy saving, and can realize single-person multi-machine operation.

7. The entire groove is made of 10MM steel plate. The double-glass observation window allows you to check the soaking status at any time.

Function

1. The impregnation time can be set;

2. It has the functions of timing alarm, motor overload protection, and phase loss protection;

3. Exhaust filtration and recycling, with dual effects of environmental protection and recycling;

4. Product storage reaches 500 pieces;

5. Full Chinese PLC control, intelligent vacuuming, to achieve bubble-free varnish, and the impregnation effect is beautiful.

Mechanism material and electrical material:

1. The main part is made of A3 material.

2. Some accessories use cold-rolled plates.

主要技术参数

| 模型 | VIT-500 |

| Overall size of impregnation machine | L2600*W660*H1400mm |

| Single cylinder size | L950*W660*H1160mm (controller size L500*W540*H1300mm) |

| Cylinder volume | L710*W540*H300mm |

| Subpan size | L660*W530*H105mm |

| Impregnation pan size | Large L550*W470*H45mm (with 2 pieces) |

| Small L600*W240*H20mm (with 4 pieces) | |

| Standard impregnation height | 80mm (height can be customized according to customer requirements) |

| Power input | AC 380V 3-phase 4-wire 50Hz (power 1HP) |

| Control equipment | Chinese and English PLC computer touch screen |

| The lifting height can be preset | The maximum stroke of the sub-trough is 60mm; the displacement accuracy is ±0.05mm. |

| Net weight (kg) | 260KG |

公司信息

瓦库斯机械厂成立于 2007 年 5 月,位于广东省东莞市。它是一家从事自动绕线机、绕线机、变压器绕线机、电机绕线机、无线线圈绕线机、SQ 共模扼流圈电感器绕线机和其他非标准绕线机的研究、开发、生产、销售和服务的专业制造商。产品畅销全国各省市,并出口到中东、欧洲、非洲、亚洲和北美等国家和地区。无论是从我们的产品目录中选择现有产品,还是为您的应用寻求工程帮助,您都可以向我们的客户服务中心咨询您的采购需求。质量是我们的文化!希望早日与您合作!

包装和运输

1.港口:上海/深圳或您的选择

包装和运输

一般包装(纸箱或塑料袋):对于小件货物,用表格和包装纸包装,以保证在运输过程中不破损。

木箱包装:对于机器设备等大型货物,我们有专门的熟练木工,他们会按照准确的厚度、密度和长度制作合适的木箱。木箱外包装上标有向上的箭头↑。木箱内将放置缓冲材料,以防止开裂和震动。我们将通知您发货单。您只需等待电话通知,然后到最近的物流站提货即可。

瓦库斯服务与实力

服务宗旨

为您提供 "快速 + 满意 + 安全 "的最佳服务。

保修期

用户收到产品后 12 个月。

保修项目

仅适用于因机器设计或制造缺陷造成的异常故障、

将提供免费维修和配件。

技术服务能力

所有具有多年经验的服务工程师都接受过专门的技术培训,能够处理各种故障问题。

指导用户准确使用和如何维护产品。

免费提供电子产品生产工艺技术咨询。

售后服务

为了保证机器的正常使用,我们会通过英文手册、视频、在线指导等方式对如何操作、使用和维护我们的产品进行培训。

使用说明

申请正确的产品完整尺寸,否则,错误的尺寸会影响使用效果。

请确保完全按照使用说明使用产品。

使用后要注意保养,防潮、防锈、防漏、防爆,定期保养和检查。这些都有助于延长产品的使用期限。

用户文件管理

在 EPR 系统中建立完善的用户文件管理,对每个产品的运行细节进行跟踪管理。用户将得到很好的照顾。

关于产品

1.产品照片:所有产品图片均为实物拍摄,产品与照片之间存在色差,色差是由拍摄光线、产品尺寸、手工技术和电脑显示屏等因素造成的。这不是质量问题。产品部件

由于技术革新和工艺改进,产品外观发生了变化。闪亮将确保产品参数不变,不影响产品的使用。

2.产品尺寸:所有参数均为人工测量,仅供参考。由于测量工具、批量产品和生产工艺的不同,会有微小偏差。实际尺寸应与最终交付产品一致。

3.质量检验:所有产品在装运前都要经过严格检验。确保良好的功能和外观。