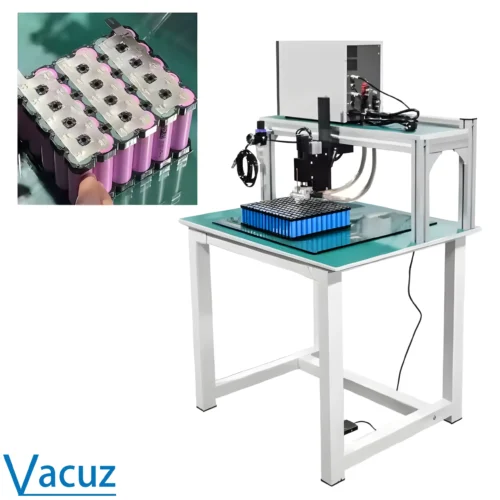

Vacuz High Frequency Cylindrical Battery Cells Paper Sticking Machine 18650 26650 32650 21700 Equipment for Battery Cell Insulating Paper Pasting

Overview:

The Battery Sticking Machine is mainly used for puching and sticking protection film, like barley paper, on cylindrical cell positive pole.

Why need sticking machine?

The battery pasted with insulating paper to avoid short circuit of the battery itself or short circuit of the battery pack during the assembly process, which may burn out the protection circuit or components, and damage the human body in the worst case.

Commonly used are barley paper, fast red bar, PVC and so on. Barley paper has good insulation, water resistance and abrasion

resistance, which can effectively prevent the positive and negative poles of the power battery pack from short-circuiting during vibration.

Usually need to paste the insulation protection position:

1. Between the contact surface of the BMS board and the battery cell: the paper is required to completely cover the contact surface of the BMS board and the battery to avoid short circuit of the battery;

2. Protect the overlap position of the different polarities of nickel strips, pads, traces and plugs and leads on the BMS board: insulation is required to completely cover the contact surface that can cause a short circuit between the two to avoid short circuit of the battery;

3. When the batteries are connected in series, the joint insulation pads should be attached to the series end, and then the nickel strip should be spot-welded in series to prevent the positive pole cell in the series from short-circuiting;

4. When the battery cells are connected in parallel, the positive pole of the battery should be attached to the barley paper device. The positive pole of the battery cell should be attached to the joint insulation pad. The positive pole of the battery can be attached to the barley paper device, and then the nickel strip can be connected in series to prevent the battery itself from short-circuiting.

How sticking machine works?

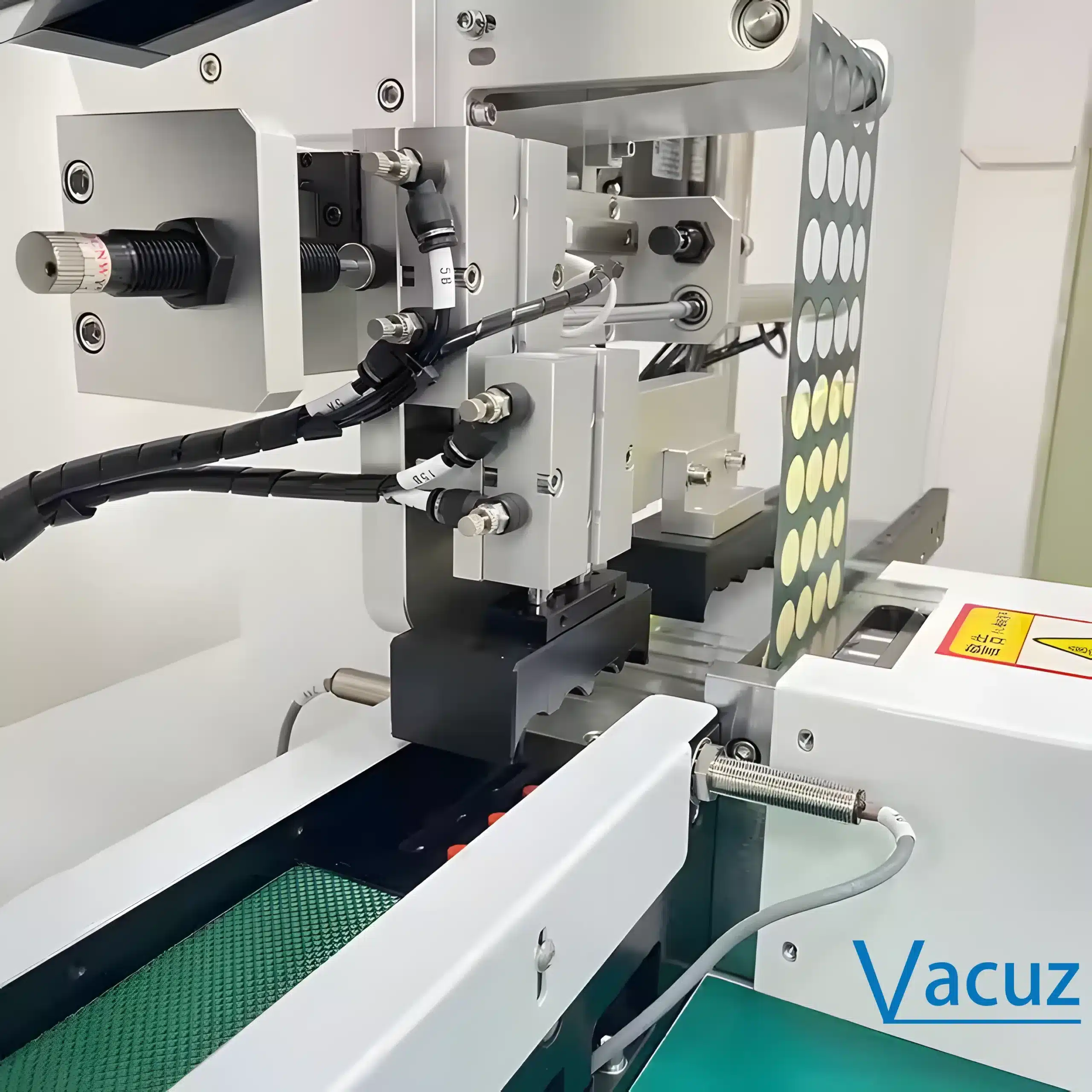

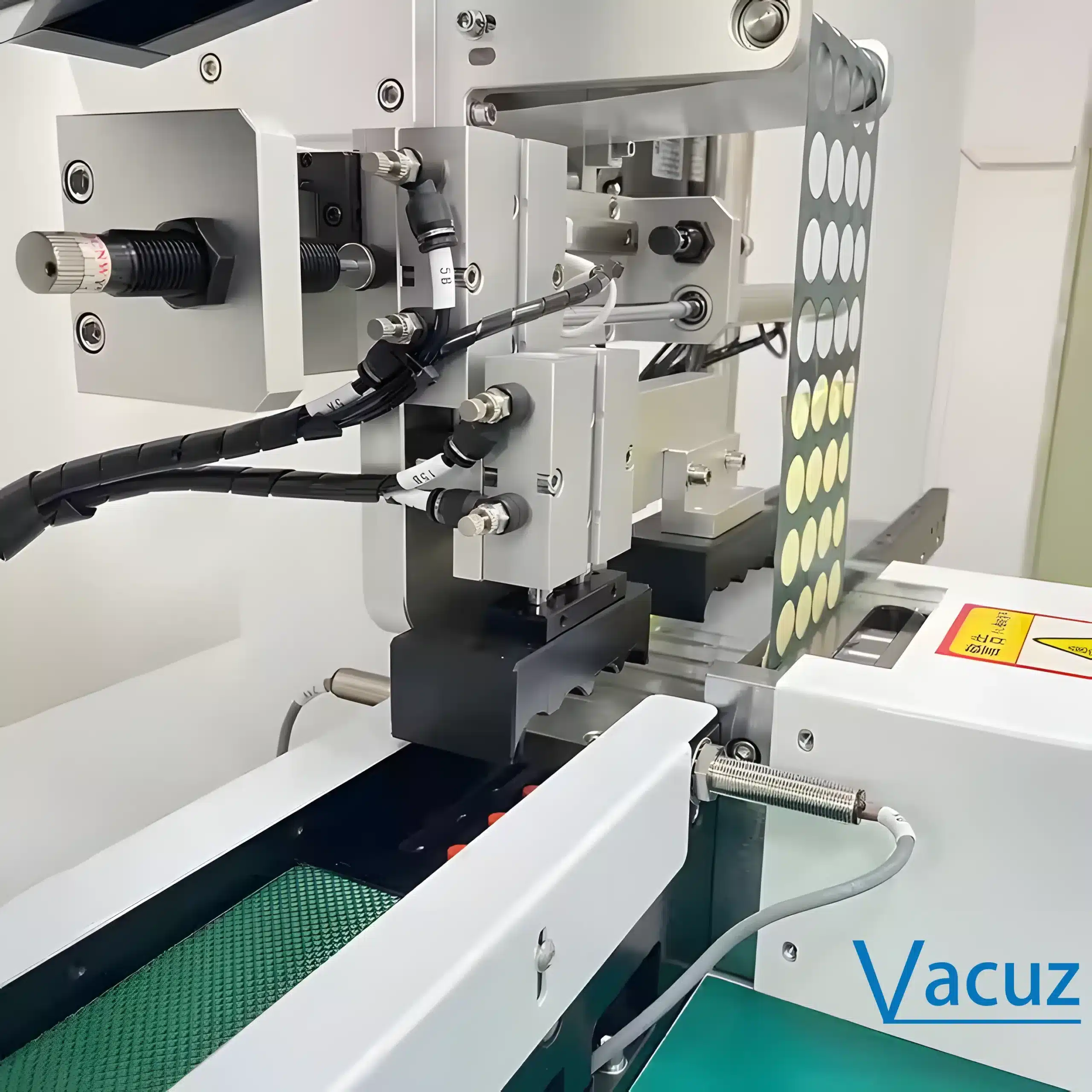

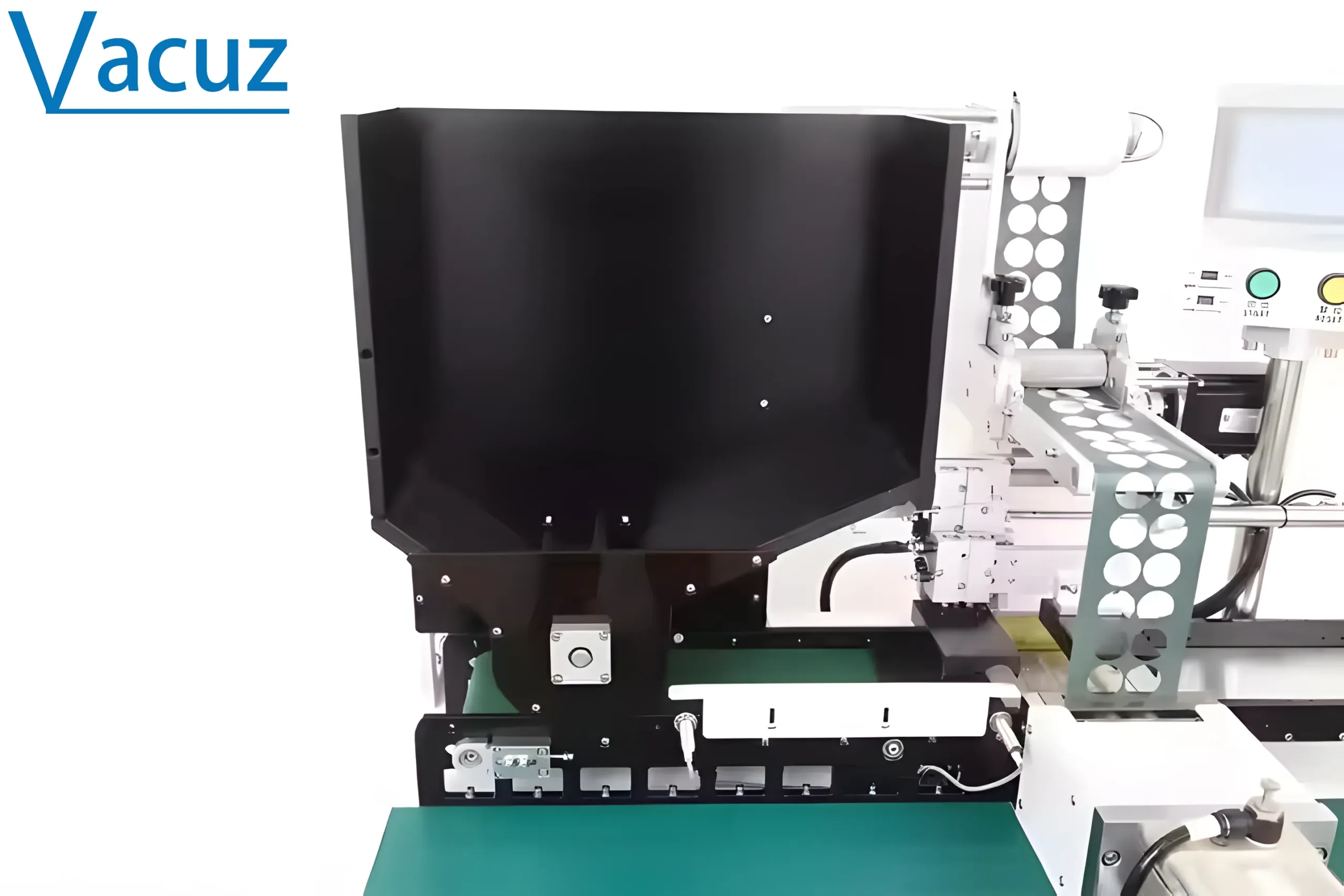

The sticking machine is controlled by microcomputer to complete the test and sorting of stepping motors and cylinders, and realize the function of sticking barley paper to qualified cells. The number of finished cylindrical cells is about 4000 per hour. The mechanical structure design is simple and generous, and the system performance is stable. In the current market, one of the most cost-effective cylindrical battery sticking barley paper equipment so far.

机器参数

|

模型

|

VAP-11

|

|

项目

|

Parameter

|

|

Type of battery

|

18650 or 21700 battery

|

|

Sticker machine frame material

|

aluminum

|

|

Feeding method

|

Manual feeding

|

|

Fitting method

|

Automatic type

|

|

Driving method

|

Pneumatic-electric type

|

|

Role object

|

Various lithium battery packs

|

|

After Warranty Service

|

Video technical support

|

|

Sticker Frame Material

|

High quality thick cold rolled steel sheet, aluminum material

|

|

Control instrument

|

contact screen,PLC programming machine and step motor

|

|

Use

|

Insulating paper on the positive electrode of the battery

|

公司信息

瓦库斯机械厂成立于 2007 年 5 月,位于广东省东莞市。它是一家从事自动绕线机、绕线机、变压器绕线机、电机绕线机、无线线圈绕线机、SQ 共模扼流圈电感器绕线机和其他非标准绕线机的研究、开发、生产、销售和服务的专业制造商。产品畅销全国各省市,并出口到中东、欧洲、非洲、亚洲和北美等国家和地区。无论是从我们的产品目录中选择现有产品,还是为您的应用寻求工程帮助,您都可以向我们的客户服务中心咨询您的采购需求。质量是我们的文化!希望早日与您合作!

包装和运输

1.港口:上海/深圳或您的选择

包装和运输

一般包装(纸箱或塑料袋):对于小件货物,用表格和包装纸包装,以保证在运输过程中不破损。

木箱包装:对于机器设备等大型货物,我们有专门的熟练木工,他们会按照准确的厚度、密度和长度制作合适的木箱。木箱外包装上标有向上的箭头↑。木箱内将放置缓冲材料,以防止开裂和震动。我们将通知您发货单。您只需等待电话通知,然后到最近的物流站提货即可。

瓦库斯服务与实力

服务宗旨

为您提供 "快速 + 满意 + 安全 "的最佳服务。

保修期

用户收到产品后 12 个月。

保修项目

仅适用于因机器设计或制造缺陷造成的异常故障、

将提供免费维修和配件。

技术服务能力

所有具有多年经验的服务工程师都接受过专门的技术培训,能够处理各种故障问题。

指导用户准确使用和如何维护产品。

免费提供电子产品生产工艺技术咨询。

售后服务

为了保证机器的正常使用,我们会通过英文手册、视频、在线指导等方式对如何操作、使用和维护我们的产品进行培训。

使用说明

申请正确的产品完整尺寸,否则,错误的尺寸会影响使用效果。

请确保完全按照使用说明使用产品。

使用后要注意保养,防潮、防锈、防漏、防爆,定期保养和检查。这些都有助于延长产品的使用期限。

用户文件管理

在 EPR 系统中建立完善的用户文件管理,对每个产品的运行细节进行跟踪管理。用户将得到很好的照顾。

关于产品

1.产品照片:所有产品图片均为实物拍摄,产品与照片之间存在色差,色差是由拍摄光线、产品尺寸、手工技术和电脑显示屏等因素造成的。这不是质量问题。产品部件

由于技术革新和工艺改进,产品外观发生了变化。闪亮将确保产品参数不变,不影响产品的使用。

2.产品尺寸:所有参数均为人工测量,仅供参考。由于测量工具、批量产品和生产工艺的不同,会有微小偏差。实际尺寸应与最终交付产品一致。

3.质量检验:所有产品在装运前都要经过严格检验。确保良好的功能和外观。

瓦库兹机视频