Motor stator winding is commonly done manually or with automated equipment. For large-volume production, manual methods cannot solve the output problem, necessitating automated winding equipment. So, what are the automation requirements for motor stator pin-type winding machines? How can labor costs be reduced? Vacuz will briefly introduce this below!

I. Core Automation Requirements

1. High-Precision Winding Control

Servo Drive System: A high-precision servo motor drives the winding head, combined with a tension control system, to achieve stable wire winding. For example, the wire diameter adaptability range can reach 0.02~1.2mm, ensuring stable winding of both fine wires (e.g., 0.1mm) and thick wires (e.g., 1.0mm).

Dynamic Tension Compensation: For multi-wire parallel winding, a time-segmented tension control technology is used: low tension guides the wire into the groove at the beginning of winding, gradually increasing to the target tension in the middle, and finishing with a low tension at the end to avoid the risk of wire breakage.

Internal slot wire routing algorithm: Based on the needle bar movement trajectory, the needle bar pressure is adjusted in real time using a force control sensor to ensure the wire is tightly embedded in the slot, reducing the wire routing misalignment rate from 3% to 0.5%.

2. Fully Automated Operation

Automated Loading and Unloading System: Integrates a robotic arm or dedicated clamp to automatically grasp, position, and clamp the stator core, achieving a positioning accuracy of ±0.02mm, and seamlessly integrates with the logistics line.

Automatic Wire Cutting and Corner Wrapping: Through pneumatic grippers and a laser positioning system, accurate control of the wrapping angle (e.g., 45°±2°) and the cutting length (e.g., 5mm±0.5mm) is achieved.

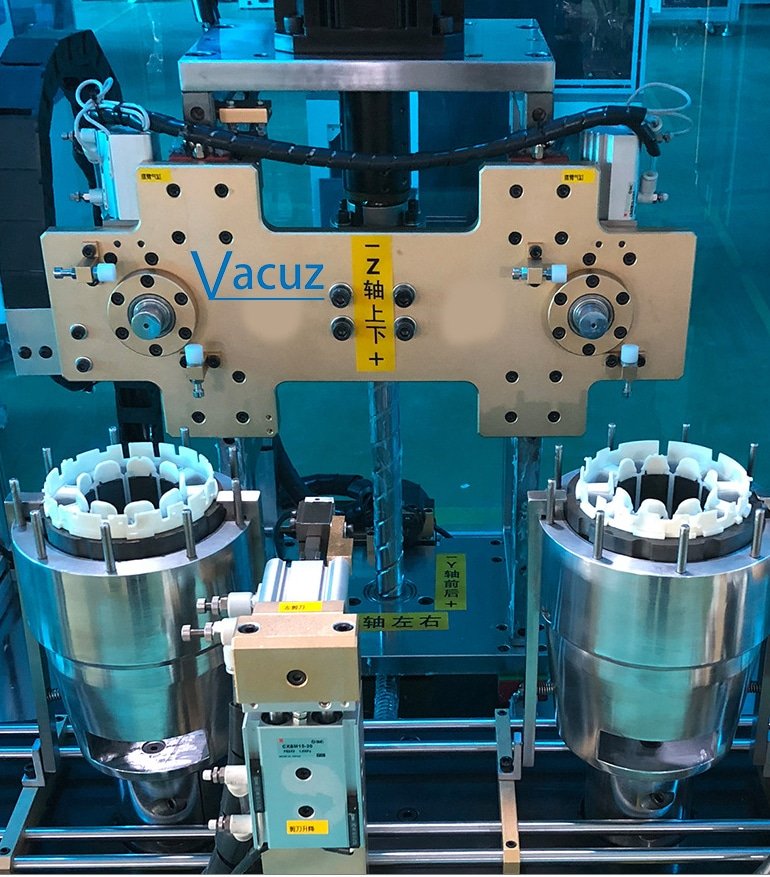

Multi-station Collaboration: Supports dual-station, four-station, and even six-station structures. Single-station winding speeds can reach 1000-3000 rpm, and multi-station efficiency is improved by 3-5 times.

3. Intelligent Detection and Quality Monitoring

Machine Vision Inspection: High-speed cameras capture the moment the wire enters the winding slot, dynamically correcting the fork angle (±2°). Combined with AI image recognition technology, defects such as broken wires, skipped wires, and abnormal turn counts are detected.

Multi-Parameter Real-Time Monitoring: Integrates tension sensors, a three-axis accelerometer, and a temperature sensor for real-time monitoring of winding quality.

Early Warning and Fault Diagnosis: When any parameter exceeds its limit, the system automatically triggers “speed reduction operation” or “emergency stop” and pushes a fault diagnosis report to the mobile device.

4. Modular and Flexible Production

Rapid Changeover Design: Dedicated winding dies are designed for different stator models. The dies have a rapid changeover function, with changeover time (including dies replacement and process parameter adjustments) ≤ 15 minutes.

Process Database Support: Stores various stator winding process parameters (such as coil turn count, winding speed, tension, etc.) to achieve rapid changeover and adapt to diverse production needs.

5. Industrial-Grade Control System

High-Performance PLC and Motion Control: Utilizing a high-performance PLC combined with a multi-axis motion controller, the system achieves coordinated control of the winding mechanism, wire laying mechanism, and loading/unloading system. It supports industrial bus protocols, ensuring high real-time performance and stability.

Human-Machine Interface: Equipped with a touchscreen operating terminal, it supports intuitive setting and monitoring of process parameters and provides production data statistics and analysis functions (such as yield rate, production efficiency, etc.).

Remote Monitoring and Maintenance: Supports remote monitoring and fault diagnosis of equipment via industrial Ethernet or 4G/5G networks. It integrates predictive maintenance functions, providing early warnings of equipment failures through data analysis.

II. Key Paths to Reducing Labor Costs

1. Reducing the Number of Direct Operators

One Person Operating Multiple Machines: Traditional semi-automatic winding machines require 1-2 operators per machine, while fully automatic needle winding machines can be managed by one person for 5-10 machines.

24-Hour Continuous Production: Fully automatic equipment can be used in conjunction with an automatic loading/unloading system to achieve 24-hour continuous production, resulting in higher output per unit time and further reducing labor requirements.

2. Reduced Skill Requirements and Training Costs

“Foolproof” Operation Mode: The equipment features automatic identification, calibration, and error correction. Operators only need to monitor the production process and handle abnormalities, eliminating the need for complex adjustments and maintenance. Ordinary workers can be trained quickly, reducing the company’s reliance on highly skilled personnel.

Standardized Operating Procedures: Through a process database and preset programs, one-click switching of winding parameters for different products is achieved, reducing operational difficulty and shortening the training cycle for new employees.

3. Improved Production Efficiency and Stability

High-Efficiency Winding: Single-station winding speeds reach 1000-3000 rpm, and multi-station equipment increases efficiency by 3-5 times, significantly shortening the production cycle.

Low Defect Rate: Precision control reduces human error, lowering the product defect rate by 30%-50%, reducing rework and scrap costs.

Data-Driven Management: The equipment automatically records production quantity, equipment status, quality parameters, and other information, reducing the need for auxiliary personnel in production report preparation and data entry, and improving management efficiency.

4. Optimize Production Process and Resource Allocation

Full-Process Automation: From stator core loading to finished product output, the entire process is automated, reducing manual intervention and lowering the workload of production scheduling and personnel coordination.

Flexible Production Capability: Modular design and quick changeover functionality allow the equipment to quickly adapt to the production needs of different stator specifications, reducing downtime caused by product changes.

5. Long-Term Cost-Benefit Analysis

Short Investment Return Cycle: Although the initial investment for fully automatic pin-winding machines is higher than that of semi-automatic equipment, the long-term savings in labor costs are significant, with a payback period typically within 1-2 years.

Reduced Hidden Costs: Reducing safety risks, material waste, and energy consumption associated with manual operation further lowers overall production costs.

What are the automation requirements for motor stator pin-winding machines? How to reduce labor costs? Vacuz has provided a brief explanation above; we hope this information is helpful!