Fully automatic brushless stator winding machines are key equipment in modern motor production. Their efficient and accurate winding capabilities directly impact motor performance and reliability. Vacuz has summarized their operating principles, core requirements, and solutions to winding challenges, along with optimization recommendations. We hope this helps!

I. Operating Principle: The Synergy of Precision Mechanics and Intelligent Control

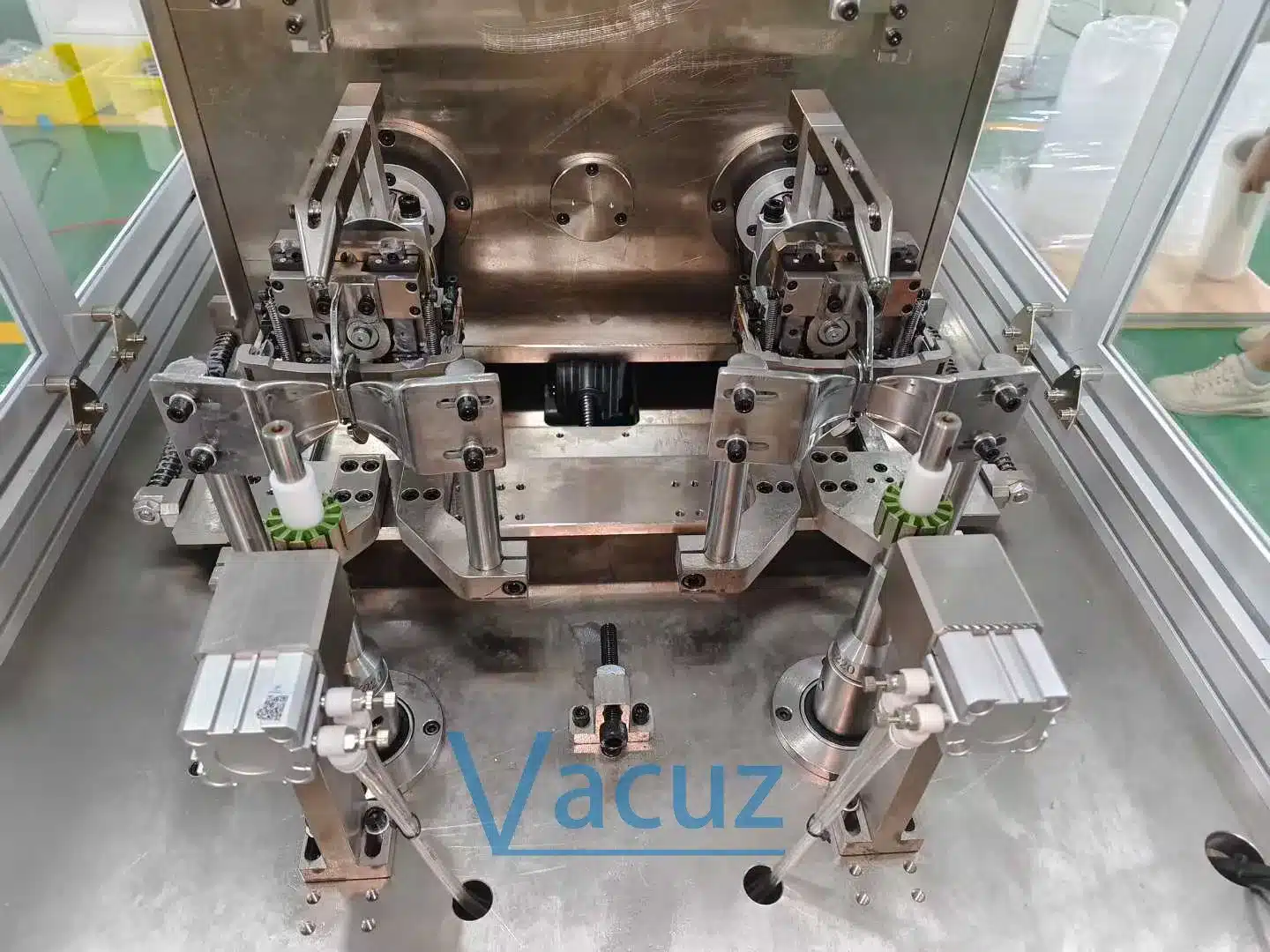

1. Mechanical Structure

Winding Head: A servo motor drives the needle bar or flying fork, ensuring accurate winding at high speeds.

Stator Clamp: A high-rigidity design with integrated vibration damping technology prevents vibration interference.

Drive System: High-precision ball screws and linear guides deliver repeatability of ≤±0.05mm, providing the foundation for layered winding.

2. Wire Feed Device

Tension Control: A closed-loop feedback system dynamically adjusts tension (±0.5N fluctuation) to accommodate varying wire diameters and speeds.

Wire Trimming and Steering: Driven by servo motors, with an error control of ±0.1mm (wire trimming) and ±0.5° (steering).

3. Intelligent Control

Path Planning: Optimizes the winding sequence based on the CAD model to avoid crossing or overlapping.

Parameter Control: The PLC/CNC system precisely adjusts the number of turns, speed, and other parameters, with an error of ≤±0.05mm between adjacent notches.

Visual Inspection: High-speed cameras monitor the wiring status in real time, automatically correcting problems such as missing wires and overlaps.

II. Core Requirements: Accuracy, Stability, and Safety

1. Accuracy

Wire routing error ≤±0.02mm, tension fluctuation ≤±3%, and insulation paper positioning error ≤±0.1mm.

Regular equipment calibration is required to ensure the accuracy of sensors and transmission components.

2. Stability

Utilizing high-rigidity guide rails and active vibration reduction algorithms, copper wire jitter amplitude is ≤±0.01mm.

Environmental Control: Maintain constant temperature (±2°C) and humidity (≤60%) to prevent softening of the enameled wire.

3. Safety

Protective covers, emergency shutdown mechanisms (response time ≤0.5 seconds), and standardized operating procedures are essential.

III. Solutions for Winding Problems

1. Wire Arrangement Disorder

Equipment Optimization: Upgrade to a high-rigidity frame and introduce an automatic lubrication system.

Intelligent Algorithm: Automatically adjust the wire arrangement strategy based on wire diameter and number of turns to reduce human error.

Visual Assistance: Real-time monitoring and alarms, supporting automatic correction.

2. Wire Damage and Breakage

Thick Wire Processing: Apply a lubricating coating and polish the die to Ra ≤0.4μm.

Thin Wire Processing: Reduce the winding speed to 80% and utilize a dynamic tension control system.

3. Interference in Multi-Wire Parallel Winding

Optimize wire spacing design (≥0.5mm) and implement real-time tension compensation (deviation ≤±0.3N).

Laser displacement sensors monitor inter-wire position (error ≤ ±0.02mm).

4. Poor equipment stability

Perform regular maintenance (clean the wire pulley, replace worn parts), and establish a health record.

Upgrade the power supply system and introduce IoT remote monitoring for predictive maintenance.

5. Inadequate mold precision

Meet strict machining standards (notch deviation ≤ ±0.03mm), polishing to Ra ≤ 0.2μm.

Laser positioning technology ensures repeatable positioning accuracy ≤ ±0.01mm.

What are the operating principles and requirements of fully automatic brushless stator winding machines? How can winding problems be addressed? Vacuz has provided a brief explanation, which we hope will be helpful!

电子邮件: sales@vacuz.com [fusion_form form_post_id=”431″ margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””][/fusion_form].