In a brushless motor winding machine, the stator and mold are indispensable components, and there are many requirements for both. If the processing or incoming materials do not meet the requirements, various winding problems can easily occur. So, what are the requirements for the stator and mold in a brushless motor winding machine? What factors affect the winding accuracy? Below, Vacuz will give you a brief introduction!

I. Requirements for the Stator

1. Parameter Compatibility

Slot Direction: Stators with outward-facing slots require a fly fork external winding machine, while stators with inward-facing slots require a pin-type internal winding machine to ensure the winding method matches the equipment.

2. Size Range:

Outer Diameter: Typically required to be between Φ20-Φ130mm; exceeding this range requires non-standard customization.

Inner Diameter: Typically between Φ12-Φ100mm. The inner diameter directly affects the selection of the number of workstations (e.g., two-station, four-station).

Stack Thickness (Height): Generally controlled between 5-80mm. Excessive stack thickness requires optimization of the pin oscillation and wire guide methods to avoid scratching or damaging the wire.

3. Structure and Material

Core Surface: Must be smooth and burr-free. Corners must be rounded to prevent scratching the enameled wire during winding.

Slot Distance: Adjusted according to wire diameter and winding requirements. For thicker wires or multiple wires wound in parallel, the slot distance needs to be increased to prevent wire jamming.

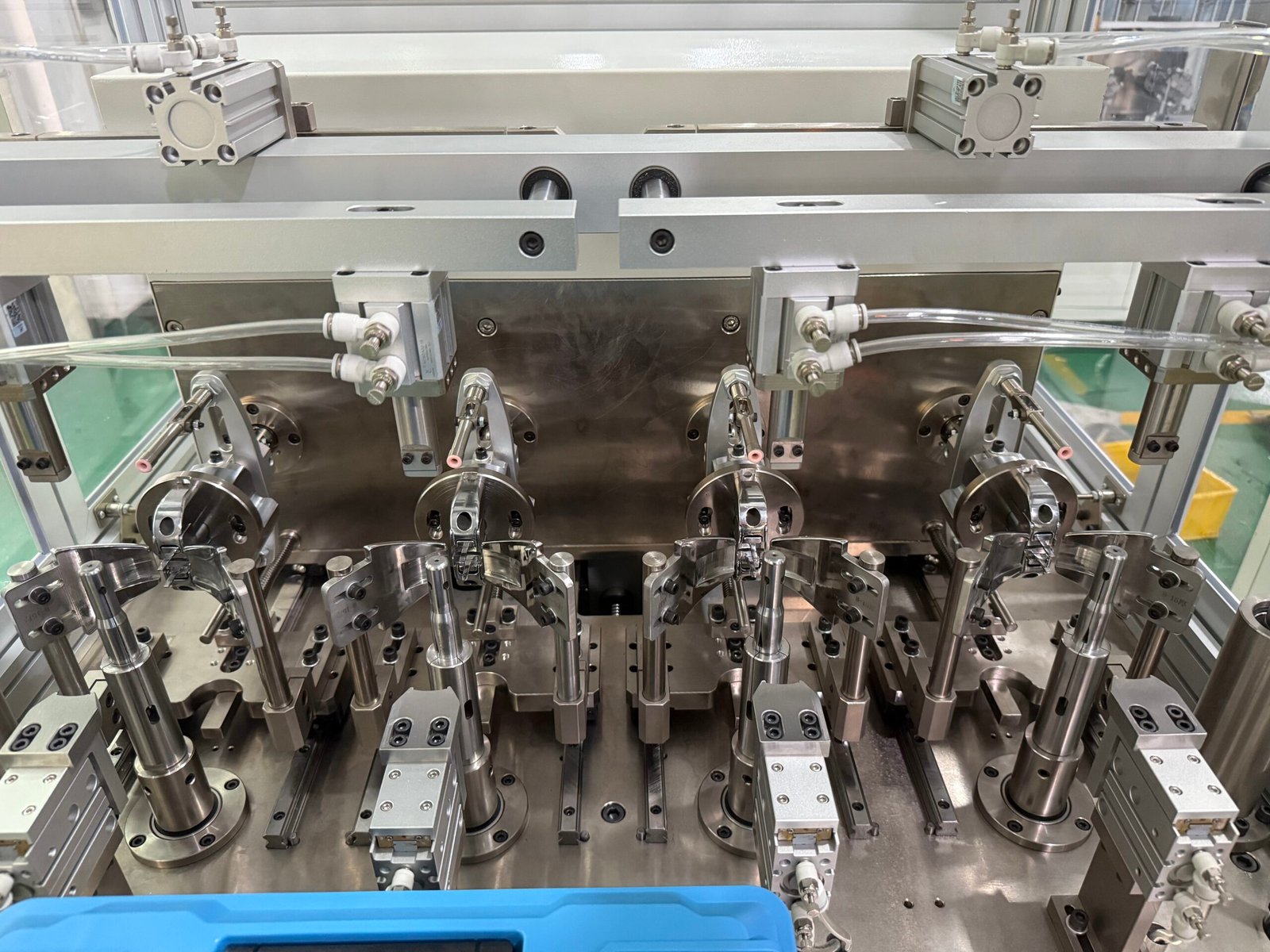

II. Requirements for the Mold

1. Precision and Tolerance

Machining Precision: Mold tolerances must be strictly controlled within the standard range (e.g., ±0.01mm) to ensure uniform clearance with the stator core.

Surface Quality: The mold surface must be smooth and burr-free to avoid scratching the enameled wire insulation layer.

2. Positioning and Fit

Positioning Accuracy: The positioning of the mold with the winding device, pin bar, wire nozzle, and other components must be accurate to prevent offset or vibration during winding.

Compatibility: The mold must support multiple stator models. Modular design (such as quick fixture replacement) reduces mold costs and downtime.

III. Factors Affecting Wire Laying Accuracy

1. Hardware Configuration

Servo Motor and Drive System: Utilizes internationally renowned servo motors and precision controllers to achieve multi-axis collaborative control, avoiding collisions and wire breakage.

Wire Laying Mechanism: Components such as lead screws, guide rails, and cylinders require high-precision machining to ensure smooth, vibration-free movement.

Tension Control System: Dynamically adjusts tension based on wire diameter and material (copper, aluminum, etc.) to prevent excessively loose (overlapping) or excessively tight (breakage).

2. Software and Control

PLC and Touchscreen System: Real-time monitoring of winding parameters (such as speed, tension, number of turns), supporting parameter storage and quick retrieval.

Wire Laying Algorithm: Optimizes the winding path through computer-aided design, reducing wire bending stress and improving slot fill factor.

3. Operation and Debugging

Debugging Techniques: Master the full-winding debugging method, gradually adjusting the mold and wiring parameters until the winding meets requirements. Tooling and Fixtures: Polishing and grinding must be meticulous to ensure no protrusions or burrs, avoiding scratches on the wire.

4. Environment and Wire

Ambient Temperature and Humidity: Operate in a workshop with a temperature of 20±2℃ and humidity of 50±5% to prevent softening of the enameled wire insulation.

Wire Quality: Enameled wires from different manufacturers may vary; winding parameters need to be adjusted according to wire diameter and material.

What are the requirements for the stator and mold of a brushless motor winding machine? What factors affect the winding accuracy? Vacuz has provided a simple explanation above; we hope this information is helpful!