Brushless motor stator a variety of different, for the selection of the winding machine is particularly critical, if the selection is not appropriate, resulting in injury, wire breakage, or product testing failed, etc., it will affect the production schedule, so brushless stator winding machine selection methods and production considerations are what Vacuz give you an analysis of it! I hope it can help you!

Hair Dryer Stator Coil Needle Winding Machine Manufacturer

Brushless stator winding machine selection method mainly includes the following steps:

1. Define the requirements: first of all, it is necessary to define the stator type, power, slot direction, outer diameter, inner diameter, stack thickness, wire diameter and so on of the enameled wire that needs to be wound. These parameters will directly affect the choice of winding machine and winding effect.

2. Selection of model: According to the direction of stator slotting, you can choose internal winding machine equipment or flying fork external winding machine equipment. At the same time, according to the stator’s outer diameter, inner diameter and thickness of the stack, select the appropriate type of winding machine to ensure the smooth progress of the winding process.

3. Consider the production capacity: according to the production needs, choose a winding machine that can meet the production capacity. If you need mass production, you can choose the winding machine with high degree of automation and high speed.

4. Precision and maintenance: precision is an important parameter of the winding machine, the higher the precision, the better the quality of the winding coil. At the same time, choosing the winding machine with simple structure and easy maintenance can reduce the maintenance cost and improve the production efficiency.

In the process of winding production, the following matters need to be paid attention to:

1. Winding planning: Before winding, you need to plan the winding of stator products, calculate the surface area of the coil, design the winding route and so on, in order to ensure the precision and efficiency of the winding process.

2. Speed control: In the winding process, speed control is the key. Too fast speed may cause damage or breakage of the thread, while too slow speed may affect the production efficiency. Therefore, it is necessary to adjust the winding speed within the range allowed by the equipment.

3. Tooling polishing: the polishing and finish of the machining mold tooling must meet the requirements, there should be no burrs or bumps, so as not to scratch the wire and affect the performance of the motor.

4. Quality inspection: Whether manual winding or automatic equipment winding, must do a good job of stator inspection to ensure the quality of winding to prevent damage to the wire, stacked wire, broken wire and other issues.

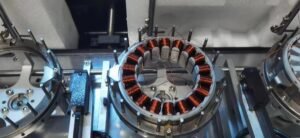

46 Stations Vacuz Precision Automatic BLDC Brushless Motor Stator Coil Needle Winding Machine

In summary, the selection and production of brushless stator winding machine need to pay attention to many aspects to ensure the smooth running of the winding process and product quality.

E-post: sales@vacuz.com